Solar Collector Absorber

Advantages:

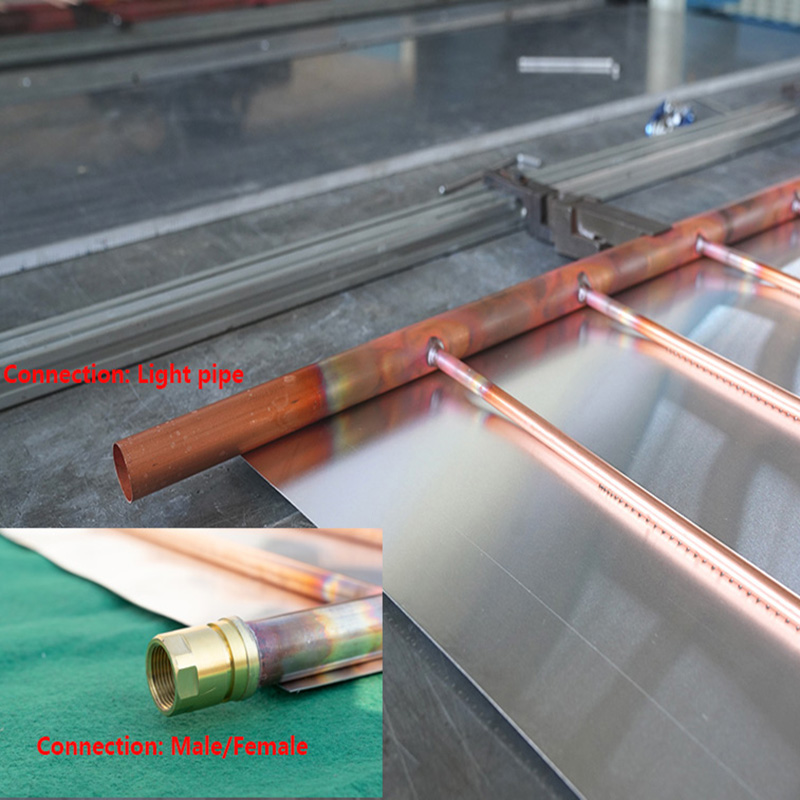

1. The laser welding Line developed a small melting pool, it means enhanced the connection strength between absorber and riser pipes, the result is promise longer life of solar absorber;

2. The appearance of solar collector without welding line is more beautiful and integrated well with building's roof;

3. The is no destroy of the surface of blue coating film, in the flat plate solar collector;

4. The distance between two welding spots is 3mm, more welding spots take high transmission to system.

Product Introduction:

High-Performance Solar Collector Absorber for Flat Plate Solar Water Heaters.

Image of a high-quality solar absorber plate with copper fins and pipes, showing the selective coating.

As the core component of any flat plate solar thermal system, our Solar Collector Absorber is engineered for maximum efficiency and durability. This critical part is responsible for converting sunlight into usable heat. Our absorbers are manufactured with precision using premium materials and advanced coating technology to ensure superior thermal performance, longevity, and reliability for OEM manufacturers and system integrators worldwide.

Product Parameters:

1. Currently, the most commonly used specifications are thickness of Al 0.3 mm & Al0.4mm, width is less than 1250mm. The coil materials are supplied.

2. Solar selective absorption coating is widely used, and the conventional application is the heat absorption part of the flat plate solar collector, which can also be used as the heat absorption part of the large heat pipe, air energy collector etc.

Coating Thickness (mm) | Width(mm) | Coating Material | |

0.3 | 750 | Aluminum Plate | Black Coating |

0.3 | 950 | Aluminum Plate | Black Coating |

0.3 | 1250 | Aluminum Plate | Black Coating |

0.4 | 750 | Aluminum Plate | Black Coating/Blue Coating |

0.4 | 950 | Aluminum Plate | Black Coating/Blue Coating |

0.4 | 1250 | Aluminum Plate | Black Coating/Blue Coating |

Working Principle:

The solar absorber is a key component that absorbs solar radiation energy into heat energy and transfers heat to water. The choice of material, structure and surface coating of the heat-absorbing core have a decisive influence on the performance of the water heater. The requirement for the heat absorption plate is to have a certain pressure bearing capacity, good compatibility with water, and high thermal performance.

Our solar absorber is the "heart" of the flat plate collector. It consists of a series of parallel riser tubes connected to a larger header pipe at each end. These tubes are bonded to a flat, wide fin that is coated with a dark, light-absorbing material.

The absorber is housed inside an insulated collector box with a glass cover. Sunlight passes through the glass, is absorbed by the coating, and converted to heat. This heat is conducted through the fin to the riser tubes, where it is transferred to the fluid (water or glycol mixture) circulating within the tubes.

1. Material: Copper-Aluminum (Al-Cu)

2. Coating: Blue/Black Solar Selective Coating

3. Bonding Technology: Laser Welding

Key Advantages & Benefits:

1. Exceptional Thermal Efficiency: Advanced selective coating ensures optimal solar absorption and minimal heat loss through emission, maximizing energy conversion.

2. Superior Durability & Corrosion Resistance: Made from high-purity copper or marine-grade aluminum alloys, our absorbers are built to withstand harsh operating conditions and prevent degradation over time.

3. Long-Term Performance Stability: The coating is designed for high temperature and humidity resistance, ensuring performance does not significantly degrade over decades of use.

4. Excellent Heat Transfer: Laser-welded or ultrasonic-welded design ensures perfect thermal bonding between the fin and the riser pipes, minimizing thermal resistance and maximizing heat conduction to the heat transfer fluid.

5. Customizable Design: We offer extensive OEM and ODM services, allowing for customization in size, pipe diameter, connection ports, and coating type to fit your specific collector design.

6. Cost-Effective: Provides the best balance of performance, quality, and price, offering outstanding value for solar collector manufacturers.

Our Factory Advantages:

1. Vertical Integration: We control the entire production process from raw material selection to coating and welding, ensuring strict quality control and cost efficiency.

2. Advanced Production Lines: Equipped with state-of-the-art ultrasonic welding machines and automated magnetron sputtering coating lines.

3. In-House R&D Laboratory: We continuously test and develop new coating formulas and bonding techniques to improve absorber performance and longevity.

4. Stringent Quality Control: Every step of production is monitored by our QC team. Each absorber is pressure tested, and coating samples are regularly tested for optical performance.

5. High-Volume Production Capacity: Our automated lines allow us to produce large quantities with consistent quality, making us a reliable partner for major OEMs.

6. 15+ Years of Specialization: We are a focused manufacturer with deep expertise specifically in solar thermal components.

7. Global Certification Compliance: Our products and processes are designed to meet international standards such as Solar Keymark, SRCC, ISO 9806, and CE requirements.

8. Expert Technical Support: Our engineering team provides full technical data and support to help you integrate our absorbers into your collector design efficiently.

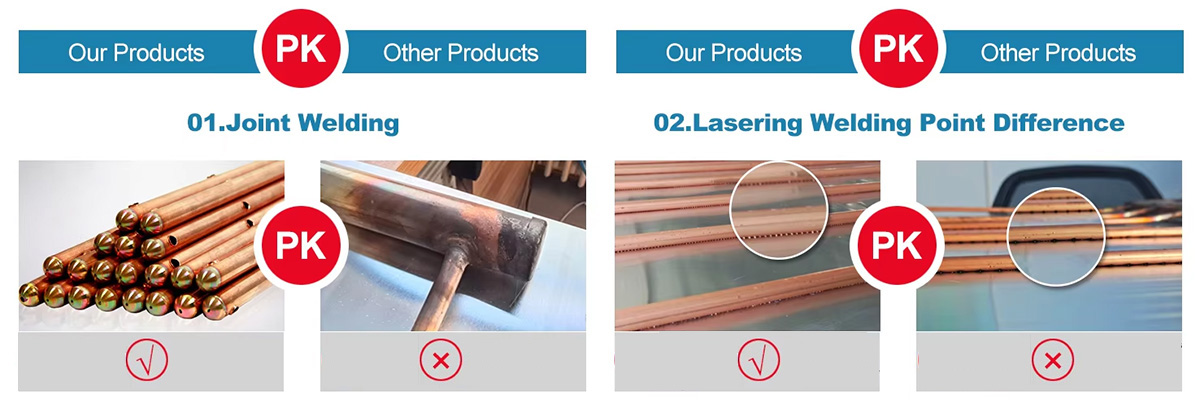

Product Advantage Comparison:

Advanced technology, compared with other companies' products.

Using high frequency welding, no leakage | Too much laser point, easy to leakage | 1. The distance between two weldign spots is 3mm, more welding spots take high transmission to system. 2. Pipes and coating welded fimly have longer life span. | 1. The distance between two weldign spots is longer 10-12mm, lower transmission. 2. Pipes and coating will be dropped, working life is short. |

Packaging and Logistics:

1. BTESolar the new solar absorber is one of our products , we are the largest factory of Solar water heater parts in Northern China.

2. BTESolar are professional in OEM the new solar absorber, generally we will use wooden case or iron stand to pack.

Application Scenarios:

1. Our absorber plates are designed for integration into a wide range of solar thermal systems:

2. Domestic Hot Water (DHW) Systems: The primary component in flat plate collectors for residential solar water heaters.

3. Solar Space Heating: Used in larger collector arrays for combi-systems that provide both hot water and space heating.

4. Industrial Pre-Heating: Ideal for systems that require pre-heating of water or other fluids for industrial processes, reducing energy costs.

5. Solar Pool Heaters: Used in efficient pool heating systems, often with polymer collectors but high-end systems use metallic absorbers.