Flat Plate Thermal Collector

As renewable energy adoption accelerates worldwide, the demand for the Flat Plate Thermal Collector has expanded significantly across both residential and commercial sectors. With global energy prices rising and governments increasing incentives for solar thermal technology, flat plate collectors remain one of the most stable and efficient solutions in the solar heating industry.

According to recent international market assessments, the global solar thermal sector is projected to surpass USD 27 billion within the next five years, with flat plate collectors accounting for a major share due to their reliability, moderate-cost structure, and broad application range. Strong growth regions include Europe, the Middle East, South America, and emerging Asia-Pacific markets, where energy diversification and decarbonization strategies continue to intensify.

Global Market Outlook of Flat Plate Thermal Collector

As renewable energy adoption accelerates worldwide, the demand for the Flat Plate Thermal Collector has expanded significantly across both residential and commercial sectors. With global energy prices rising and governments increasing incentives for solar thermal technology, flat plate collectors remain one of the most stable and efficient solutions in the solar heating industry.

According to recent international market assessments, the global solar thermal sector is projected to surpass USD 27 billion within the next five years, with flat plate collectors accounting for a major share due to their reliability, moderate-cost structure, and broad application range. Strong growth regions include Europe, the Middle East, South America, and emerging Asia-Pacific markets, where energy diversification and decarbonization strategies continue to intensify.

Industry Trends and Procurement Dynamics

Several new trends are shaping the global Flat Plate Thermal Collector sector. One of the most notable developments is the rising preference for high-efficiency coated absorber plates that maintain stable performance even under lower irradiation conditions.

The integration of automated circulation pumps, antifreeze systems, and smart temperature controllers is also becoming standard, improving operational safety and reducing maintenance workloads.

Long-tail keywords gaining traction among international buyers include “high-efficiency flat plate collector,” “solar thermal water heating system,” “pressurized flat plate solar collector,” and “commercial thermal solar panel.” These search behaviors highlight the market’s increasing demand for premium performance, system durability, and project-grade reliability.

Technical Specifications and Performance Characteristics

Technical performance indicators remain essential to buyer decision-making when evaluating Flat Plate Thermal Collector products. Key specifications include:

• Absorber Efficiency: Advanced selective coatings achieve absorption rates above 93%, significantly improving energy conversion.

• Thermal Output: Standard units deliver 500–900 W/m² depending on climate and mounting orientation.

• Operating Pressure: Pressurized models typically withstand 0.6–1.2 MPa, making them suitable for multi-story buildings.

• Heat Transfer Fluid: Glycol-water mixtures ensure frost protection and stable heat transfer.

• Glass and Insulation: Low-iron tempered glass paired with high-density insulation minimizes thermal loss.

Such specifications ensure that Flat Plate Thermal Collector units operate reliably across diverse conditions, from tropical climates to cooler, high-altitude regions.

Product Structure and Functional Design

A Flat Plate Thermal Collector is engineered to capture and transfer solar heat efficiently through a carefully structured assembly. Key components include:

• Absorber Plate: Copper-aluminum composite sheets coated with high-selectivity materials.

• Riser Tubes and Manifold: Hydraulically balanced channels transport heated fluid with minimal resistance.

• Tempered Solar Glass: Low-reflectivity glass enhances irradiation absorption.

• Insulation Layer: Mineral wool or polyurethane insulation reduces heat loss.

• Outer Casing: Weather-resistant aluminum or galvanized steel construction ensures durability.

The combination of these elements results in a robust thermal collector capable of supporting residential hot water systems, commercial installations, and industrial preheating applications.

Manufacturing Process and Quality Standards

The manufacturing of Flat Plate Thermal Collector systems follows a controlled, precision-engineered workflow. Absorber plates undergo laser welding to riser tubes for optimal heat transfer performance. Selective coatings are applied using vacuum deposition to ensure long-term adhesion and efficiency.

The glazing is tested for transmittance and impact resistance, while insulation materials are evaluated for density, thermal conductivity, and moisture resistance.

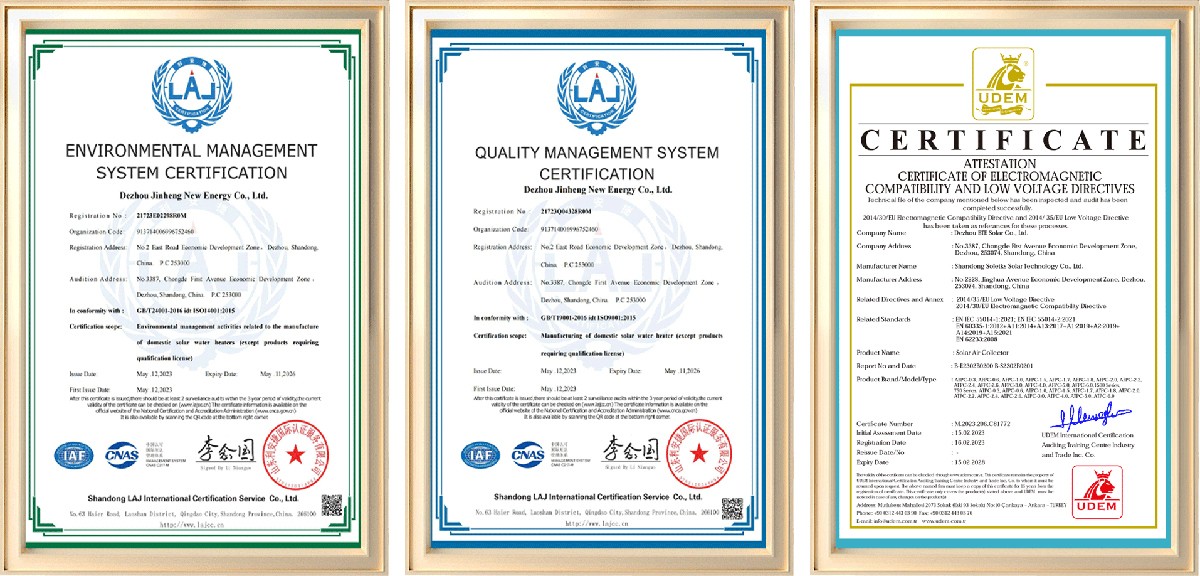

Fully assembled collectors undergo pressure testing, high-temperature cycling, UV exposure simulation, and long-term durability trials. Compliance with ISO, CE, SRCC, and key regional certifications ensures the product meets global installation and safety standards demanded by international buyers.

Applications Across Key Sectors

Flat Plate Thermal Collector systems support a wide range of applications, including:

• Residential Hot Water Systems for single-family homes and apartments.

• Hotels and Hospitality requiring large-volume hot water.

• Hospitals where continuous thermal output is needed for sanitation and cleaning.

• Commercial Buildings such as office complexes, schools, and public facilities.

• Industrial Processes including preheating, washing, and food processing.

Their reliability and stable thermal output make them suitable for projects requiring predictable performance and long-term operational savings.

International Buyer Preferences and Common Challenges

Global buyers prioritize quality, long-term performance, and efficient after-sales support. Major purchasing considerations include:

• Verified thermal efficiency backed by third-party test reports.

• Strong frame construction and corrosion resistance.

• Flexible mounting options for diverse roof structures.

• Easy integration with existing tanks, pipelines, and smart controllers.

Common pain points include inconsistent product specifications, insufficient insulation leading to heat loss, lack of engineering documentation, and transportation damage during logistics. Buyers increasingly seek suppliers that offer engineered design support, installation guidance, and long-term spare parts availability.

Future Development and Market Potential

The future outlook for Flat Plate Thermal Collector technology remains highly positive. Innovations such as ultra-low-emissivity selective coatings, improved glazing transmittance, and AI-based system monitoring are expected to enhance both efficiency and operational lifespan.

As more countries implement solar thermal mandates for residential and commercial infrastructure, the global market will continue expanding, presenting abundant opportunities for contractors, distributors, and project developers.

We support international buyers with technically advanced, third-party validated Flat Plate Thermal Collector systems designed for premium thermal performance and long service life.

Conclusion: Reliable Thermal Solutions for Global Projects

The Flat Plate Thermal Collector has established itself as an essential component in modern solar thermal systems. Its robust design, strong efficiency profile, and adaptability across climate zones make it a preferred choice for global renewable energy initiatives.

We welcome international project developers, distributors, and engineering firms to request detailed technical datasheets, performance test reports, system design support, and sample evaluations to streamline procurement and ensure project success.

FAQs

1. What is the typical efficiency range of a Flat Plate Thermal Collector?

High-quality units typically achieve thermal efficiency of 70–80% under standard conditions, depending on absorber coating and glazing.

2. Can these collectors be used in cold climates?

Yes. Systems using glycol-based heat transfer fluids and insulated piping deliver stable performance even in low-temperature environments.

3. How long is the expected service life?

Well-manufactured collectors generally operate efficiently for 15–25 years with routine maintenance and proper installation.

4. Do you offer customized system configurations?

Yes. We provide tailored collector sizing, tank integration options, and mounting solutions for residential, commercial, and industrial applications.

For quotations, engineering drawings, test data, or sample requests, please contact our technical team to begin your procurement process.

Applicable Scene:

Used in residential hot water systems and commercial solar heating projects.