Heat Pipe Split Solar Water Heater System

The Heat Pipe Split Solar Water Heater System integrates evacuated tube collectors, copper heat pipes, solar manifold, pump station, controller, and insulated storage tank. Key performance metrics include thermal efficiency, heat loss coefficient, stagnation temperature, daily output, and pressure rating.

Concise Definition

A Heat Pipe Split Solar Water Heater System uses evacuated tubes with heat pipes to capture solar thermal energy and transfer it to a separated water tank through a circulation loop. It delivers stable hot water for commercial, industrial, and institutional applications with high efficiency and modular scalability.

Technical Specifications of Heat Pipe Split Solar Water Heater System

The Heat Pipe Split Solar Water Heater System integrates evacuated tube collectors, copper heat pipes, solar manifold, pump station, controller, and insulated storage tank. Key performance metrics include thermal efficiency, heat loss coefficient, stagnation temperature, daily output, and pressure rating.

Typical Technical Parameters

• Collector Type: Borosilicate 3.3 evacuated tubes with copper heat pipe

• Tube Dimensions: 58×1800 mm or 47×1500 mm

• Heat Pipe Material: Oxygen-free copper, distilled medium

• Manifold Shell: Aluminum or SUS304 with polyurethane insulation

• Daily Output: 60–140 L/m² depending on climate

• Working Pressure: 0.6–0.8 MPa for split pressurized systems

• Tank Volume: 200–5000 L (customizable for industrial load)

• Controller: Differential temperature controller with anti-freeze logic

• Pump Station: High-temperature circulation pump with flow meter

System Structure and Manufacturing Process

The Heat Pipe Split Solar Water Heater System is engineered for durability, modular expansion, and stable thermal performance. Its manufacturing process follows strict thermal engineering standards for long-term reliability.

System Structure

• Evacuated Tube Collector: Double-layer glass tubes with selective coating

• Heat Pipe Core: Phase-change medium enabling rapid start-up and high heat transfer

• Header Manifold: Copper pipeline transferring heat to heat exchanger

• Circulation Loop: Pump station + controller + flow valves

• Storage Tank: Thickened polyurethane insulation + inner steel liner

• Mounting Frame: Aluminum or galvanized steel with 25–45° tilt angle

Manufacturing Workflow

1. Select borosilicate glass and coat with ALN/ALN-SS selective layers.

2. Produce copper heat pipes using vacuum filling and sealing.

3. Assemble heat pipes into tubes and conduct thermal shock testing (−30°C to 200°C).

4. Apply TIG welding for copper manifold pipelines.

5. Integrate collector, frame, and manifold to complete the collector module.

6. Build insulated pressure tank using SUS304 liner + polyurethane foaming.

7. Assemble controller, pump station, and safety valves.

8. Conduct full-system pressure tests and optical efficiency tests.

Market Trends and Industry Data

According to IEA and Solar Heat Worldwide, global solar thermal capacity surpassed 540 GWth, with heat pipe split systems growing 6–8% annually due to rising industrial and commercial hot water demand. Adoption is strongest in hotels, agriculture processing, food factories, hospitals, and residential complexes.

Key drivers include energy cost reduction, decarbonization targets, and subsidy programs across Asia, EU, and Africa.

Industry Comparison Table

| Technology | Efficiency | Maintenance | Climate Suitability | Cost |

|---|---|---|---|---|

| Heat Pipe Split Solar Water Heater System | High | Low | Cold/Hot | Medium |

| Flat-Plate Collector System | Medium | Medium | Warm Regions | Low |

| Heat Pump Water Heater | Medium | Medium | Moderate Climates | High |

| Electric Boiler | Low | Low | All | High (operating cost) |

Pain Points and Solutions

Pain Point 1: Unstable Hot Water Output in Cloudy Conditions

Solution: Integrate auxiliary heating (heat pump or electric heater) with controller logic for automatic backup.

Pain Point 2: Difficult System Sizing for Large Commercial Loads

Solution: Use engineering calculation (see example below) to determine collector area and storage volume.

Pain Point 3: High Maintenance Cost of Traditional Systems

Solution: Heat pipe split systems require minimal maintenance; only tube replacement every 8–12 years.

Engineering Calculation Example

Required collector area A for daily hot water Q (liter) with ΔT temperature rise:

A = (Q × 4.186 × ΔT) ÷ (η × H)

Where:

• η = thermal efficiency (0.55–0.65 for heat pipe collectors)

• H = average daily solar radiation (kWh/m²) converted to kJ

Step-by-Step Installation Workflow (Highly Practical)

1. Determine load profile and peak-hour consumption.

2. Calculate collector area using engineering formula.

3. Choose appropriate tank volume and pressure rating.

4. Install mounting frame with required tilt and orientation.

5. Install collectors and connect heat pipes to manifold.

6. Connect circulation loop and pump station.

7. Run controller configuration and safety valve testing.

8. Conduct system flushing, air-purging, and thermal performance testing.

Selection Guide for Wholesalers and EPC Contractors

1. Evaluate heat pipe material: oxygen-free copper ensures fast thermal response.

2. Choose collector insulation: polyurethane ≥ 45 mm improves energy retention.

3. Verify manifold welding quality: TIG welding reduces leakage risk.

4. Confirm controller functions: anti-freeze, backup heater control, and holiday mode.

5. Consider local solar radiation: match collector size to regional climate data.

6. Check pressure rating: minimum 0.6 MPa for commercial buildings.

7. Inspect tank liner: SUS304 or enamel with ≥ 0.5 mm thickness.

Risk Alerts and Mitigation Plans

Risk: Incorrect collector orientation → poor performance.

Solution: Align within ±15° of true south (north in southern hemisphere).

Risk: Overheating during low consumption periods.

Solution: Use heat dissipation mode + backup circulation pump.

Risk: Low-quality glass tubes failing under thermal shock.

Solution: Require −30~200°C thermal shock report from manufacturer.

Real Application Scenario

A 200-room hotel adopted a 120-tube Heat Pipe Split Solar Water Heater System combined with a 3000-L tank. Energy bills dropped by 62%, with stable 24-hour hot water availability. Collector uptime exceeded 99%, and payback was achieved within 2.7 years.

FAQ

1. How long does a Heat Pipe Split Solar Water Heater System last?

Typically 15–20 years, with tubes replaced every 8–12 years depending on climate conditions.

2. Is the system suitable for cold climates?

Yes. Heat pipes start rapidly at low temperatures, making them ideal for regions with frost.

3. Can it work with existing boilers?

Yes. The split configuration integrates easily with gas boilers, heat pumps, or electric heaters.

4. How much maintenance is required?

Only periodic flushing and occasional tube replacement.

5. What is the difference between heat pipe and U-pipe collectors?

Heat pipes offer faster start-up, higher efficiency, and easier tube replacement.

6. How to size the tank for a commercial complex?

General rule: 1.2–1.5 times the daily hot water demand at ΔT = 35–45°C.

7. Does it work during cloudy days?

Yes, combined with auxiliary heating.

8. Are heat pipe systems safe for high pressure?

Yes. Split pressure tanks support 0.6–0.8 MPa for multi-story buildings.

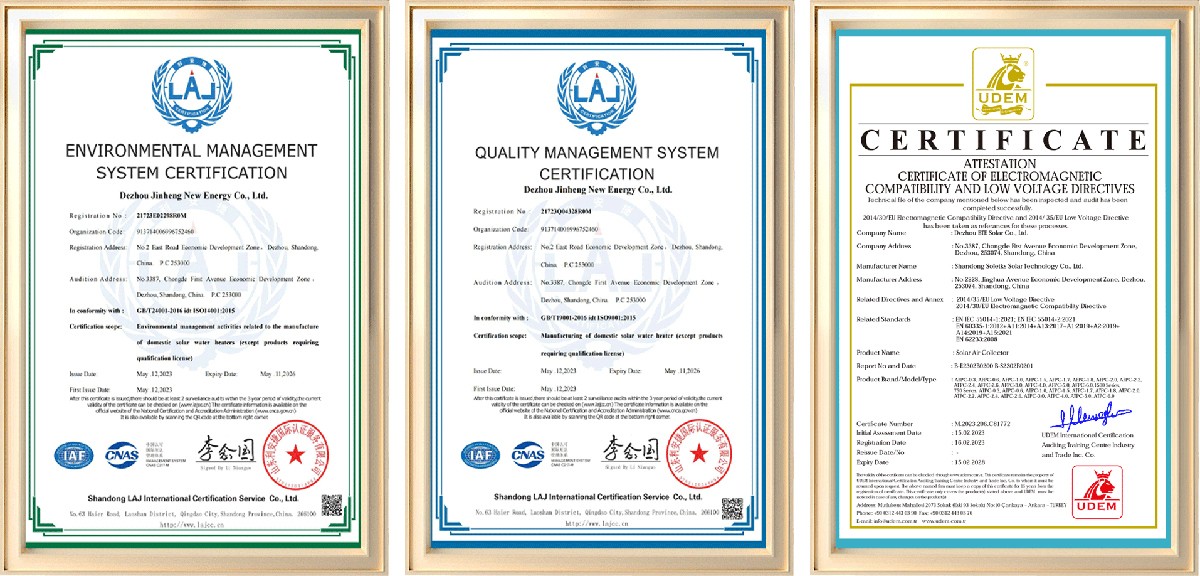

9. What certifications should wholesalers request?

ISO 9806, Solar Keymark, CE, and performance tests based on IEA SHC standards.

10. How does the controller prevent freezing?

It activates forced circulation when temperature drops below programmed thresholds.

Commercial CTA (Wholesalers, EPC, Government Projects)

Looking for high-efficiency Heat Pipe Split Solar Water Heater Systems for large-scale commercial or government projects? We supply engineering-grade collectors, project-ready tanks, pump stations, and OEM manufacturing with strict quality control. Contact our engineering team for system sizing, quotations, and turnkey project support.

Author

Written by a Renewable Energy Technical Engineer with 12+ years of experience in solar thermal system design, industrial hot water engineering, and international project consulting. Data referenced from IEA and Solar Heat Worldwide.

Accessories & fittings:

Honors and Qualifications: