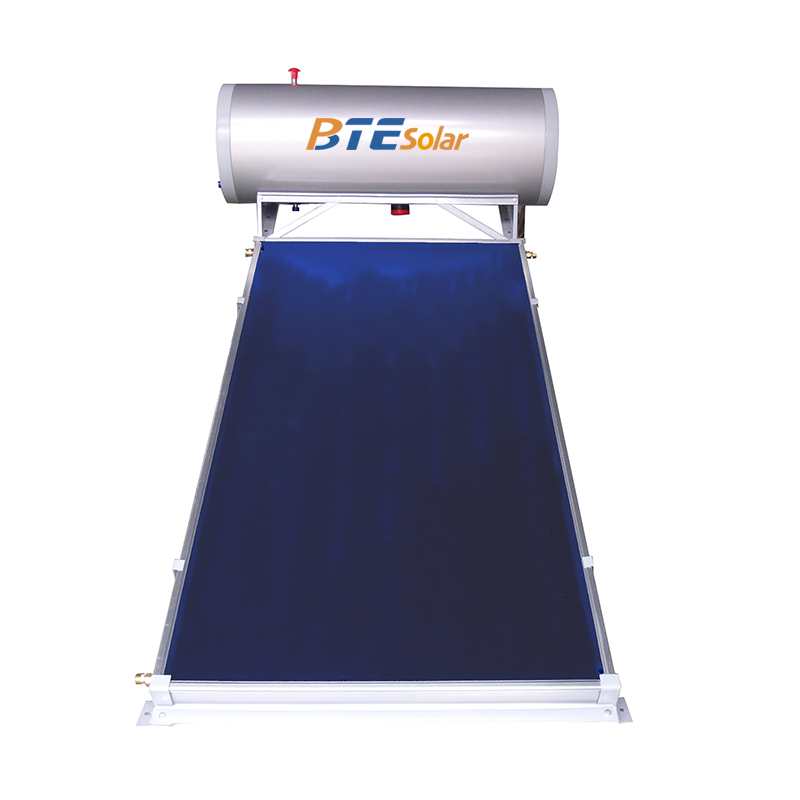

Flat Plate Solar Powered Water Heater

The Flat Plate Solar Powered Water Heater market has experienced significant growth as nations worldwide accelerate the transition toward renewable energy solutions. Rising energy costs, carbon emission reduction policies, and government incentives for solar water heating have made these systems increasingly attractive for residential, commercial, and industrial applications.

Market research indicates that the global solar thermal industry now exceeds USD 20 billion annually, with flat plate systems forming a substantial share. Europe, Southeast Asia, the Middle East, and Latin America represent key growth regions due to urban expansion, sustainability initiatives, and widespread adoption in hotels, hospitals, and multi-residential buildings.

Global Market Overview for Flat Plate Solar Powered Water Heater

The Flat Plate Solar Powered Water Heater market has experienced significant growth as nations worldwide accelerate the transition toward renewable energy solutions. Rising energy costs, carbon emission reduction policies, and government incentives for solar water heating have made these systems increasingly attractive for residential, commercial, and industrial applications.

Market research indicates that the global solar thermal industry now exceeds USD 20 billion annually, with flat plate systems forming a substantial share. Europe, Southeast Asia, the Middle East, and Latin America represent key growth regions due to urban expansion, sustainability initiatives, and widespread adoption in hotels, hospitals, and multi-residential buildings.

Emerging Trends Driving Market Expansion

Several trends are reshaping the global demand for Flat Plate Solar Powered Water Heater systems. The shift toward high-efficiency pressurized systems capable of supplying stable hot water to multi-story buildings has become a critical development.

Intelligent monitoring and automation are increasingly integrated, providing real-time temperature control, circulation regulation, and system protection against overheating or freezing.

Hybrid solar water heating solutions combining flat plate collectors with auxiliary electric or gas systems are gaining attention for regions with inconsistent sunlight. Long-tail keywords such as “residential solar water heater,” “commercial flat plate solar heater,” and “high-efficiency solar hot water system” have seen growing relevance in procurement searches.

Technical Specifications of Flat Plate Solar Powered Water Heater

Technical performance is a decisive factor in international procurement of flat plate systems. Key parameters include:

• **Collector Efficiency:** Modern flat plate collectors achieve 70–80% thermal efficiency under standard test conditions.

• **Operating Pressure:** Pressurized models operate at 0.6–1.0 MPa, suitable for high-rise and multi-story buildings.

• **Tank Capacity and Insulation:** Tank sizes range from 100L to over 5,000L, with high-density polyurethane or glass wool insulation minimizing heat loss.

• **Heat Exchanger Type:** Internal copper coils, dual-coil, or external plate exchangers ensure optimal energy transfer.

• **Control System:** Digital or programmable controllers regulate circulation pumps, temperature, and safety functions.

These parameters ensure reliable performance for various applications, including residential hot water, commercial laundry, and industrial processes.

System Structure and Functional Components

A complete Flat Plate Solar Powered Water Heater consists of several interrelated components:

• **Flat Plate Collector:** Absorbs solar radiation and converts it into thermal energy efficiently.

• **Hot Water Storage Tank:** Provides insulated storage and temperature stability.

• **Circulation Mechanism:** Thermosiphon or pump-assisted systems facilitate fluid transfer between collectors and tanks.

• **Controller and Safety Devices:** Include sensors, valves, pressure relief devices, and anti-corrosion rods.

These elements work together to provide a reliable, energy-efficient hot water supply for diverse environments.

Manufacturing Process and Quality Assurance

Manufacturing Flat Plate Solar Powered Water Heater systems requires precision engineering and rigorous quality control. Collector panels are made from copper-aluminum absorbers coated with selective solar-absorptive layers and protected by tempered borosilicate glass. Tanks are fabricated from stainless steel or coated steel using automated welding processes to ensure structural integrity.

Insulation materials are tested for density and thermal retention, while assembled collectors undergo heat, pressure, and durability tests. Digital controllers and pumps are validated for stability and response accuracy. Compliance with ISO, CE, and SRCC standards assures reliability and international market acceptance.

Applications Across Residential, Commercial, and Industrial Sectors

Flat Plate Solar Powered Water Heater systems are widely applicable:

• **Residential:** Providing daily hot water for kitchens and bathrooms.

• **Hotels and Resorts:** Meeting high-volume hot water demands efficiently.

• **Hospitals:** Supporting sterilization, laundry, and patient care.

• **Factories and Food Processing Plants:** Preheating, cleaning, and other thermal processes.

• **Schools, Sports Centers, and Hostels:** Supplying showers and accommodation facilities.

Government and rural renewable energy programs also adopt these systems for sustainable energy initiatives.

International Buyer Preferences and Common Challenges

Global buyers prioritize efficiency, durability, and ease of installation when sourcing Flat Plate Solar Powered Water Heater systems. Key considerations include:

• **Long Service Life:** Corrosion-resistant tanks and durable collectors.

• **Verified Efficiency:** Supported by performance data rather than theoretical claims.

• **Flexible Installation:** Rooftop, split, or integrated systems for diverse project needs.

• **After-Sales Support:** Availability of spare parts, technical manuals, and professional guidance.

Common challenges include inconsistent quality from low-cost suppliers, inadequate insulation, collector breakage during shipping, and insufficient technical documentation. Addressing these issues is critical to buyer satisfaction and project success.

Future Outlook for Flat Plate Solar Heating Solutions

With increasing focus on decarbonization, energy efficiency, and sustainable infrastructure, the demand for Flat Plate Solar Powered Water Heater systems is projected to grow steadily. Technological innovations, such as selective coating enhancements, smart control systems, and hybrid configurations, will further improve efficiency, performance, and longevity.

We are committed to supplying high-performance, reliable solar water heating solutions to international contractors, distributors, and project developers.

Conclusion: Reliable Flat Plate Solar Water Heating for Sustainable Projects

Flat Plate Solar Powered Water Heater systems are essential for modern energy planning, reducing operational costs, and supporting global sustainability efforts. Their versatility and efficiency make them the preferred choice for residential, commercial, and industrial applications.

We encourage buyers to request technical datasheets, performance reports, customized system designs, and sample evaluations. Expert support is available to ensure proper system selection, installation, and long-term operational reliability.

FAQs

1. What are the advantages of a flat plate collector over other types?

Flat plate collectors offer high efficiency in moderate climates, robust construction, and lower maintenance compared to other collector types.

2. Can a flat plate solar water heater work in cloudy or cold regions?

Yes. Pressurized and hybrid systems with auxiliary heaters ensure consistent hot water supply even in low sunlight conditions.

3. How long is the typical lifespan of a flat plate solar water heater?

High-quality systems can last 15–25 years with proper maintenance and usage.

4. Are customized systems available for hotels, factories, or multi-story buildings?

Yes. We can supply tailored tank capacities, collector configurations, and installation solutions to meet specific project requirements.

For quotations, technical datasheets, or sample requests, please contact our engineering team to start your procurement process.

Working Principle

Engineered for year-round operation, this high-yield solar water heating module combines military-grade corrosion resistance with intelligent thermal regulation. The multi-layer absorption system features copper-enhanced heat pipes within a reinforced aluminum casing, while the thermal buffer zone prevents overnight heat loss. Perfect for regions with fluctuating weather patterns, delivering consistent hot water regardless of external conditions.