Solar Selective Coating

1. Enhanced Durability: Resists degradation from UV exposure, moisture, condensation, and thermal cycling, ensuring long service life (often 20+ years).

2. High-Temperature Stability: Advanced coatings maintain performance under sustained high temperatures and intense solar flux in CSP systems without significant oxidation or degradation.

3. Corrosion Resistance: Protects the underlying absorber substrate (usually metal) from corrosion in humid, saline, or chemically aggressive environments.

4. Cost-Effectiveness (Long-Term): Higher initial cost is offset by significantly greater energy yield and longer lifespan compared to non-selective coatings (like black paint), leading to lower lifetime cost per kWh.

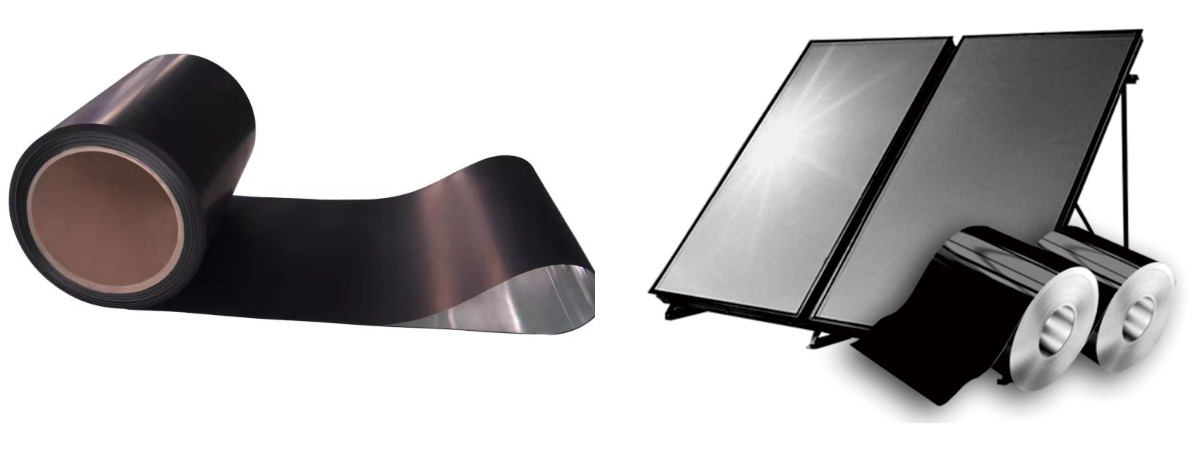

5. Versatility: Adaptable to various collector types (flat plate, evacuated tube, CSP receivers) and applications (low-temp water heating to high-temp power generation).

Product Introduction:

Maximize Solar Thermal Efficiency & Durability:

Within BTE Solar is diversified industrial portfolio, the company holds a leading market share in the solar core materials sector, driven by its outstanding core technologies and advanced manufacturing capabilities. BTE Solar is a high-tech enterprise dedicated to the research, production, and sales of advanced nanomaterials. It is the world’s only supplier capable of producing both nano black chrome solar spectrum selective absorption coatings (black coating) and vacuum magnetron sputtering (PVD) solar spectrum selective absorption coatings (blue coating), positioning it as a global leader in solar thermal absorption technologies.

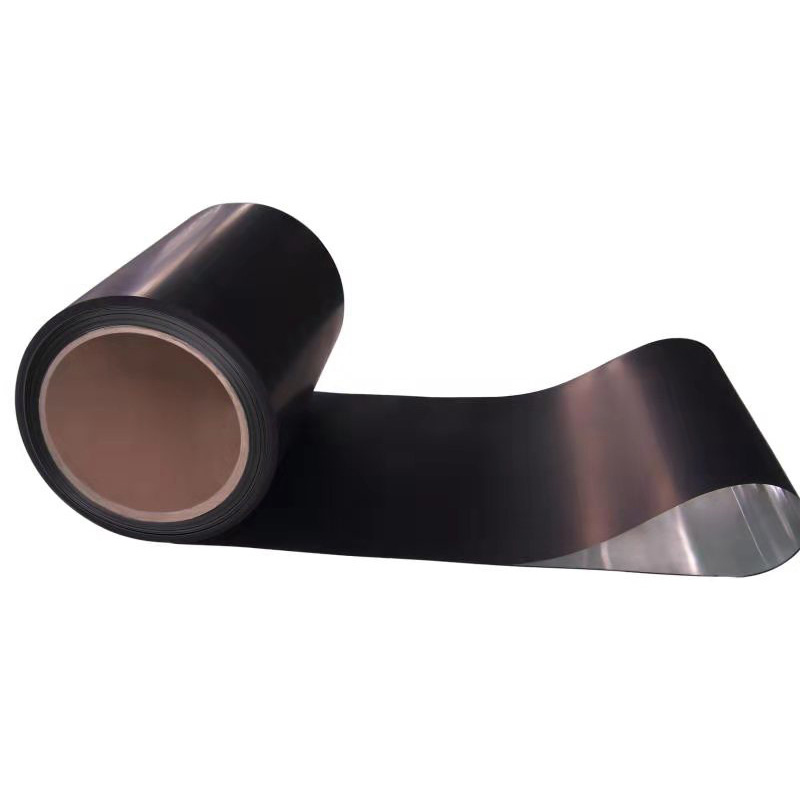

D-DOS (Black Film) Coating

1. Solar Absorptance: α = 94% ±2% (@AM1.5)

2. Outstanding durability against weathering and salt spray, enabling wider application adaptability

3. Cost-effective performance with reliable quality using Black Solar Coating coating technology

Technical Parameters:

Model | Base Material | Coaing Type | Absorption ratio (%) | Emission ratio (%) |

thickness:0.3/0.4mm width:750/950/1200/1250mm Customizable | AI | Black coating film | 94±2% | 12+2% |

thickness:0.3/0.4mm width:750/950/1200/1250mm Customizable | AI | Blue coating film | 95+2% | 5+2% |

Key Features & Benefits:

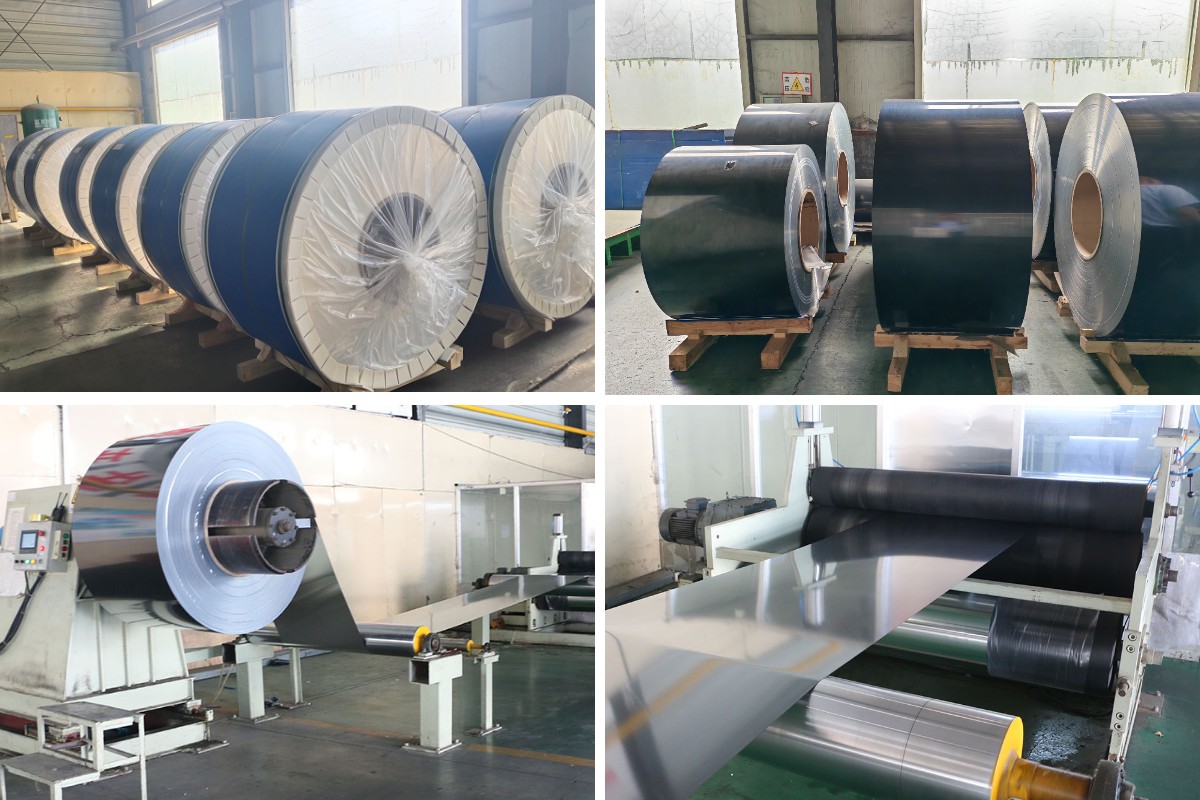

The company is located in the Dezhou Economic and Technological Development Zone in Shandong Province, widely known as the “Sun City of China.” In 2025, its magnetron sputtering roll-to-roll production line will officially be put into operation. The facility will have an annual production capacity of 5 million square meters of nano black chrome solar selective absorption coatings and 2 million square meters of high weather-resistant exterior wall heating panels.

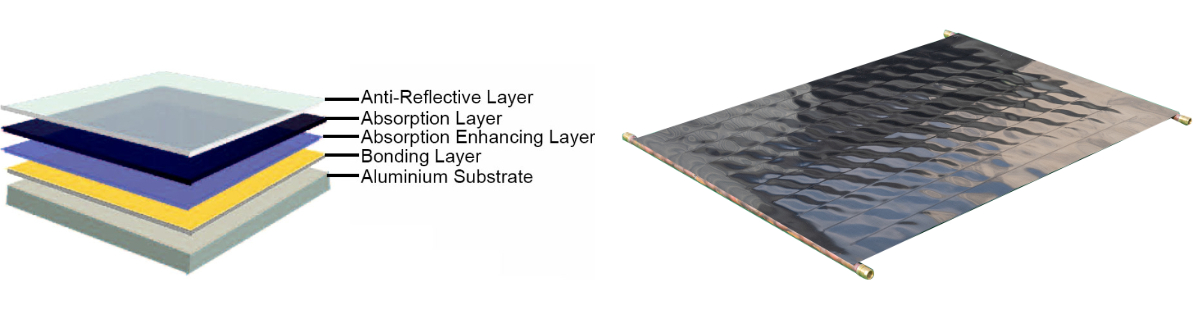

The nano black chrome solar selective absorption coating is an upgraded version of the traditional black titanium film, characterized by high photothermal conversion efficiency, long service life, and low overall cost. It represents a cutting-edge advancement in both new energy technologies and microscale materials.

Production Details:

The second-generation coating production line, independently designed and developed by the company, effectively addresses the shortcomings of the first-generation product—such as poor performance stability, residual backside coating that affects welding, uneven coating thickness, and unstable optical properties. These issues have been fundamentally resolved. With the upgraded formulation, the second-generation nano black chrome selective absorption coating achieves an absorption rate greater than 94% and an emissivity below 8%, improving performance by more than 20% compared to the first-generation product.

BTE Solar has established deep collaborative partnerships with the Institute of Semiconductors of the Chinese Academy of Sciences, Tsinghua University, and Shandong University, forming an integrated industry–academia–research development model. Its innovation capabilities are at the forefront of the industry. The company also boasts a high-caliber team of top-tier experts and management professionals dedicated to the research and development of new materials, technologies, and products in the field of renewable energy. To date, BTE Solar has secured and industrialized multiple patents across key technological domains, including solar thermal conversion, energy storage materials, thermal dissipation materials, and infrared functional materials.

Packaging and logistics:

Applications:

Solar Water Heaters/Hot Water Systems:

1. Application: This is the most mature and widely used market. A heat-absorbing film is applied to the surface of the collector's absorber plate (flat-plate collector) or the inner tube of an evacuated tube (evacuated tube collector).

2. Function: Efficiently absorbs sunlight to heat water or a heat transfer fluid for use in domestic hot water, hotel hot water supply, swimming pool heating, and other applications.

3. Key: The coating must exhibit excellent weather resistance, high temperature and humidity resistance, and long-term stability.

Solar Heating Systems:

1. Application: Similar to hot water systems, but on a larger scale, these systems are used to provide winter heating for buildings (such as homes, greenhouses, and factory floors).

2. Function: Heats a heat transfer fluid (typically antifreeze) and releases the heat through floor heating, fan coil units, or radiators.

3. Key: High efficiency is required at moderate to low temperatures (typically 40-80°C).

Industrial Process Heat:

1. Application: Providing medium- and low-temperature heat (80°C - 250°C) required for industrial processes such as food processing (e.g., drying, cleaning, and cooking), textile printing and dyeing (hot water and steam), electroplating, chemical processing (preheating), wood drying, and seawater desalination (multi-effect distillation or preheating before MED).

2. Function: Replacing or partially replacing traditional fossil fuel (e.g., natural gas, coal) boilers, reducing energy costs and carbon emissions.

3. Key Point: This is a highly promising growth area for solar thermal utilization. The heat-absorbing film must maintain high thermal efficiency and stability (resistance to high-temperature aging and oxidation) even at high operating temperatures and be suitable for use in concentrating solar collectors (e.g., trough and Fresnel).

International Certificates: