Enamel Indirect Flat Plat Solar Water Heater

The global market for the enamel indirect flat plate solar water heater has expanded significantly over the past decade as governments and industries accelerate the adoption of renewable heating technologies. This system is widely used in residential, commercial, and light-industrial applications across Europe, the Middle East, Latin America, and Southeast Asia. Supported by energy-efficiency regulations and rising electricity costs, the demand for high-performance solar thermal systems shows consistent annual growth.

Industry reports indicate that the broader solar water heating sector is growing at a rate of 6–8% annually, with indirect flat-plate systems gaining the most traction due to their durability, freeze-resistant performance, and compatibility with diverse climates. As the market moves toward longer-lifespan equipment, the enamel indirect flat plate solar water heater is increasingly favored for its corrosion-resistant tank construction and stable thermal output.

Global Market Overview

The global market for the enamel indirect flat plate solar water heater has expanded significantly over the past decade as governments and industries accelerate the adoption of renewable heating technologies. This system is widely used in residential, commercial, and light-industrial applications across Europe, the Middle East, Latin America, and Southeast Asia. Supported by energy-efficiency regulations and rising electricity costs, the demand for high-performance solar thermal systems shows consistent annual growth.

Industry reports indicate that the broader solar water heating sector is growing at a rate of 6–8% annually, with indirect flat-plate systems gaining the most traction due to their durability, freeze-resistant performance, and compatibility with diverse climates. As the market moves toward longer-lifespan equipment, the enamel indirect flat plate solar water heater is increasingly favored for its corrosion-resistant tank construction and stable thermal output.

Key Market Trends and Global Demand Drivers

Several major trends are shaping the development of modern solar thermal systems. First, international buyers are placing greater emphasis on corrosion control and heat-retention efficiency, both of which are core strengths of enamel-coated tanks. Second, stricter environmental guidelines in regions such as the EU and GCC require buildings to adopt renewable heating solutions, accelerating system installations in both new projects and retrofits.

Long-tail search queries such as “indirect solar water heating system,” “enamel-coated solar tank solution,” “flat plate solar thermal collector,” “frost-resistant solar heating system,” and “closed-loop solar water heater” reflect the specific needs of procurement managers seeking stable and low-maintenance hot water supply solutions. These trends indicate a strong shift toward durable, low-risk performance and sustainable heating technologies.

Technical Specifications and Performance Parameters

The enamel indirect flat plate solar water heater is engineered to provide consistent hot water output through a closed-loop heat exchange process. A flat-plate collector absorbs solar radiation and transfers the captured heat to a heat-transfer fluid, which circulates through a coil inside an enamel-lined storage tank. This indirect configuration prevents scale buildup and protects against freezing, making it suitable for both warm and cold climates.

Key technical parameters include: • Collector efficiency: typically 60%–75% depending on absorber coating

• Heat-transfer fluid options: non-toxic glycol or specialty anti-freeze fluids

• Storage tank volume: 100L–500L for residential systems; 500L–2000L for commercial applications

• Enamel coating thickness: 0.3–0.6 mm, applied by high-temperature sintering

• Operating pressure: 6–12 bar

• Thermal output: varies from 2.5–4.5 kWh/m² depending on solar irradiation levels

With improved absorber coatings and advanced insulation materials, modern systems achieve more stable performance during winter and cloudy conditions. These design improvements contribute to increased product longevity and reduced maintenance requirements.

Product Structure and Component Composition

A typical enamel indirect flat plate solar water heater consists of three principal units: the flat-plate collector, the enamel-coated storage tank, and the circulation system.

Flat-plate collector: A high-transmittance tempered glass cover, aluminum frame, selective absorber sheet, and copper heat pipes work together to ensure maximum solar energy capture.

Enamel storage tank: Manufactured with steel plates coated internally with high-temperature enamel, the tank is designed to resist corrosion, scaling, and thermal shock. Polyurethane foam insulation further improves heat retention.

Closed-loop circulation system: This subsystem uses pumps, valves, and heat-exchange coils to transport heat-transfer fluid between the collector and the tank. The indirect design ensures superior hygiene and longer equipment lifespan compared with direct systems.

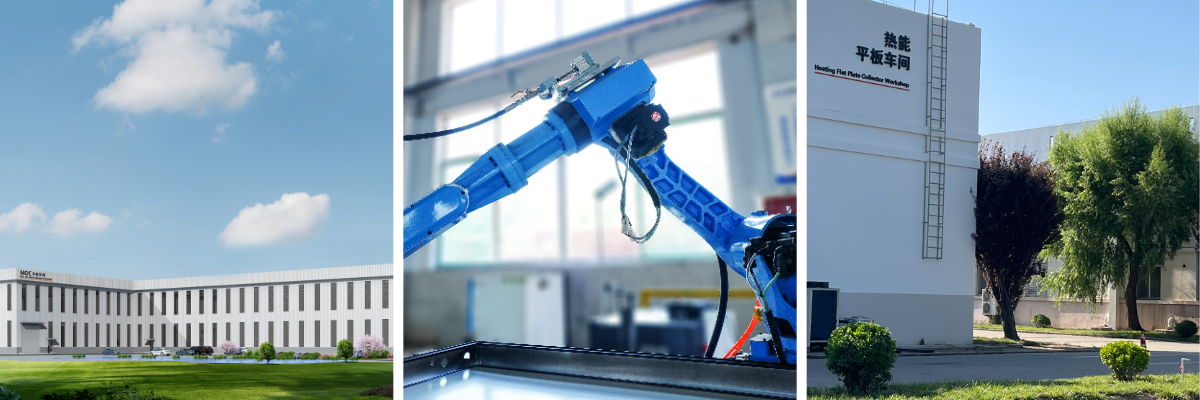

Manufacturing Process and Quality Control

The manufacturing of an enamel indirect flat plate solar water heater requires strict process control to achieve long-term stability. Tank fabrication begins with precision cutting and welding, followed by automatic enamel spraying. The enamel layer is fused at high temperature—typically above 800°C—to form a chemically bonded protective coating.

Collector production involves absorber sheet processing, laser welding of copper risers, and panel lamination. Each collector undergoes pressure leakage testing, mechanical load evaluation, and UV resistance testing. The final assembly stage includes thermal performance simulation, pressure endurance verification, and long-cycle reliability assessments. These quality control measures align with international standards such as CE, ISO, and Solar Keymark.

Applications and Advantages in Residential and Commercial Projects

The enamel indirect flat plate solar water heater is widely deployed in villas, apartment complexes, hotels, schools, and small industrial facilities requiring stable hot water supply. The indirect closed-loop system is especially advantageous in regions with freezing winters or hard-water conditions, where direct systems may encounter scaling or corrosion.

Major advantages include: • Long service life due to enamel anti-corrosion protection

• Enhanced hygiene because potable water does not flow through collector circuits

• High thermal efficiency under diverse climate conditions

• Simplified maintenance and reduced operational cost

International Buyer Preferences and Procurement Pain Points

Global buyers evaluate enamel indirect flat plate solar water heater systems based on performance reliability, certification compliance, and tank durability. Procurement managers typically request detailed performance curves, collector absorption data, enamel composition certificates, and long-term pressure resistance documentation.

Common purchasing pain points include limited lifespan of poor-quality enamel coatings, insufficient insulation, freeze-related system failures, and unclear installation guidelines. Buyers also express concerns regarding spare parts availability, long-distance logistics, and after-sales technical support. Suppliers who provide transparent specifications, professional installation manuals, and customizable system configurations have a clear competitive advantage in international markets.

Conclusion

As global sustainability initiatives accelerate, the enamel indirect flat plate solar water heater is positioned as a critical solution for renewable water heating across both developed and emerging markets. Its durability, efficiency, and adaptability to diverse environments make it one of the fastest-growing categories in the solar thermal sector.

We invite procurement teams, project developers, and distributors to request detailed datasheets, product samples, and customized quotations. Our engineering specialists are available to support system design, performance evaluation, and long-term technical planning.

Frequently Asked Questions (FAQ)

1. What is the typical service life of an enamel indirect flat plate solar water heater?

With proper installation and regular maintenance, the service life generally ranges from 12–20 years, depending on enamel quality and collector design.

2. Can the system operate efficiently in cold climates?

Yes. The indirect closed-loop design with anti-freeze fluid makes the system well-suited for regions with freezing temperatures.

3. What installation conditions are required?

A south-facing roof or open area with adequate sunlight, stable mounting structure, and access for piping connections are key installation requirements.

4. Do you support OEM specifications or custom tank sizes?

Yes. We offer customization for tank capacity, enamel thickness, collector size, heat-exchanger configuration, and pressure ratings.

For project pricing, technical drawings, or sample evaluation, please contact our team. We are ready to provide a professional solution tailored to your application needs.

Honors and Qualifications: