Stainless Steel Flat Plate Solar Water Heater

As global energy reforms accelerate, demand for durable and high-efficiency solar heating equipment continues to increase among residential, commercial, and industrial sectors. The Stainless Steel Flat Plate Solar Water Heater has emerged as one of the most stable and reliable solutions in the renewable thermal equipment category. Its corrosion-resistant structure and consistent thermal performance make it attractive to long-term investors and project contractors seeking resilient solar hot water solutions.

Industry reports indicate that the global solar thermal market surpassed 540 GWth of installed capacity, with flat plate solar collector system deployments remaining a dominant segment. Markets in Europe, the Middle East, Southern Africa, Southeast Asia, and Latin America exhibit high growth rates due to ongoing construction, tourism facility expansion, and government-supported clean energy programs. As stainless steel systems offer superior longevity under diverse climate conditions, procurement volume is projected to grow steadily over the next decade.

Global Market Landscape for Stainless Steel Flat Plate Solar Water Heater Systems

As global energy reforms accelerate, demand for durable and high-efficiency solar heating equipment continues to increase among residential, commercial, and industrial sectors. The Stainless Steel Flat Plate Solar Water Heater has emerged as one of the most stable and reliable solutions in the renewable thermal equipment category. Its corrosion-resistant structure and consistent thermal performance make it attractive to long-term investors and project contractors seeking resilient solar hot water solutions.

Industry reports indicate that the global solar thermal market surpassed 540 GWth of installed capacity, with flat plate solar collector system deployments remaining a dominant segment. Markets in Europe, the Middle East, Southern Africa, Southeast Asia, and Latin America exhibit high growth rates due to ongoing construction, tourism facility expansion, and government-supported clean energy programs. As stainless steel systems offer superior longevity under diverse climate conditions, procurement volume is projected to grow steadily over the next decade.

Key Trends Driving the Solar Heating Industry

Technological advancements and rising sustainability requirements are driving strong adoption of the Stainless Steel Flat Plate Solar Water Heater across global projects. One major trend is the increasing preference for corrosion-resistant solar water heater designs, especially in coastal regions and high-humidity climate zones. Stainless steel tanks and frames significantly reduce long-term maintenance costs compared with standard steel systems.

The integration of smart controllers, temperature sensors, and circulation pumps into high-efficiency solar heating system configurations is becoming standard for commercial projects. In addition, international engineering firms now prioritize solar systems featuring higher absorber efficiency, improved insulation materials, and optimized heat transfer pipelines to maximize year-round output. These trends collectively reinforce the competitive position of stainless steel flat plate technology in both pressurized solar water heater and open-loop system installations.

Technical Specifications of Stainless Steel Flat Plate Solar Water Heater Systems

Modern systems are engineered for long operating life and stable thermal conversion. Typical technical characteristics include:

• 304 or 316 stainless steel water tank with corrosion-resistant finish

• High-transmittance low-iron tempered glass (3.2–4.0 mm)

• Selective absorber coating with 92%–95% solar absorption rate

• Copper or aluminum heat-transfer piping system

• High-density polyurethane insulation for effective heat retention

• Pressurized working design for consistent flow and delivery in multi-story applications

By integrating these components, the Stainless Steel Flat Plate Solar Water Heater delivers reliable performance in both domestic hot water and commercial solar hot water solution projects such as hotels, hospitals, dormitories, and industrial facilities.

Product Structure and Performance Advantages

A typical system includes a flat plate collector, insulated stainless steel water tank, and circulation pipeline. The stainless steel construction offers enhanced resistance to scaling, oxidation, and long-term weather exposure. Combined with a selective absorber plate and insulated housing, the collector maintains strong heating output throughout variable seasons.

Compared with alternative solar heating technologies, flat plate systems offer balanced performance under direct sunlight and diffuse radiation, making them suitable for both tropical and temperate climate zones. For international project developers, this versatility ensures predictable energy savings and reduced operating costs across an array of installation environments.

Manufacturing Process and Quality Assurance Standards

The manufacturing of the Stainless Steel Flat Plate Solar Water Heater involves a sequence of precision-controlled processes. These include stainless steel tank forming, welding, pressure testing, absorber coating application, collector assembly, glass lamination, insulation injection, and final product inspection. Each stage requires strict compliance with solar thermal engineering standards to ensure pressure stability, heat retention efficiency, and structural durability.

Quality assurance procedures include corrosion resistance testing, thermal shock evaluation, UV aging tests, insulation performance verification, and long-term water pressure endurance assessments. Compliance with recognized testing frameworks ensures that system performance aligns with global engineering requirements for renewable heating systems.

Global Buyer Preferences and Procurement Challenges

International procurement teams prioritize durability, heat efficiency, and compatibility when selecting a Stainless Steel Flat Plate Solar Water Heater. Stainless steel tanks are often required for commercial and industrial projects where long-term reliability is essential. Buyers also seek detailed performance curves, pressure ratings, installation drawings, and test reports before confirming purchase orders.

Common challenges include ensuring system compatibility with existing pipelines, confirming pressure requirements, and managing installation procedures in multi-story buildings. Buyers expect clear documentation, strong after-sales support, and packaging that protects the flat plate collector during international shipping. Suppliers offering complete technical guidance and customized solutions typically see higher order conversion rates.

Frequently Asked Questions (B2B)

Q1: What information is required for an accurate quotation?

Project capacity, collector size, tank volume, building height, climate conditions, and type of circulation system.

Q2: Are stainless steel tanks suitable for coastal regions?

Yes. Stainless steel construction provides resistance to corrosion, humidity, and salt exposure, making it ideal for marine climates.

Q3: How long does a Stainless Steel Flat Plate Solar Water Heater last?

High-quality systems generally operate 15–20 years with proper maintenance and correct installation.

Q4: Can technical drawings and installation manuals be provided?

We provide full technical documentation including drawings, performance data sheets, and installation guidelines.

Professional Call-to-Action

For engineering firms, distributors, and project contractors seeking durable and energy-efficient solar heating equipment, the Stainless Steel Flat Plate Solar Water Heater offers a proven long-term solution. We welcome global buyers to request quotations, detailed technical specifications, and sample evaluations. Our engineering team can support system design, performance calculations, and customized commercial solar hot water solution planning for projects of all scales.

Authoritative Notes

• Market data reference: International Energy Agency (IEA) Solar Heating and Cooling Programme.

• Technical indicators based on widely applied solar collector and tank pressure testing standards.

Product Structure And Schematic Diagram:

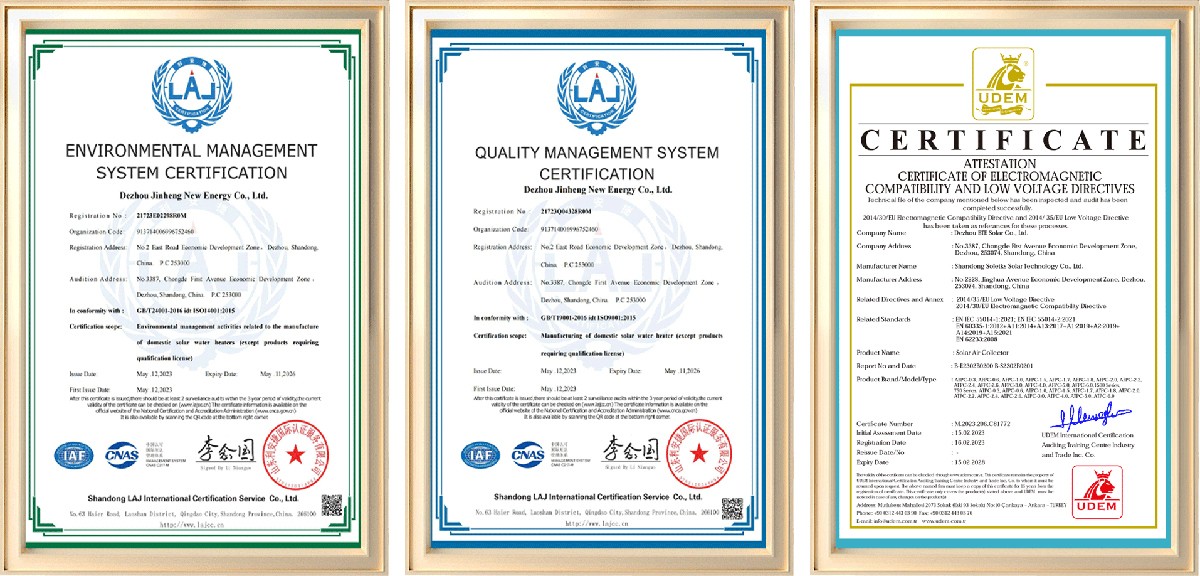

Honors and Qualifications: