Solar Thermal Collector System

Manufacturing Process

1. Material preparation & surface cleaning

2. Selective absorber coating using vacuum sputtering or oxidation

3. Copper tube-welding and bonding to absorber plate

4. Glass cutting & sealing under high temperature

5. Frame assembly with weatherproof sealing

6. Fluid pressure testing & thermal performance inspection

7. Packaging with anti-vibration protection

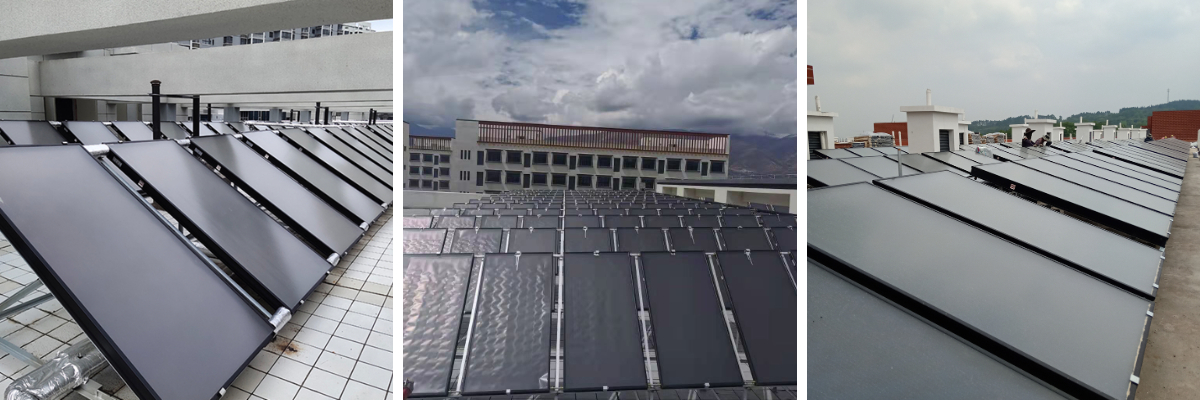

Solar Thermal Collector System Definition

A Solar Thermal Collector System is a high-efficiency technology engineered to convert solar radiation into usable thermal energy for commercial and industrial facilities. It delivers sustainable heated water or thermal fluid, reducing fuel costs and carbon emissions in long-term operations.

Technical Specifications & Parameters

| Parameter | Value Range | Engineering Notes |

|---|---|---|

| Thermal Efficiency | 70%–85% | Depends on absorber coating & insulation |

| Operating Temperature | 50–180°C | Varies by flat plate/tube type |

| Pressure Rating | 6–12 bar | Commercial-grade installations |

| Heat Transfer Fluid | Water / Water-Glycol | Frost protection for cold regions |

| Collector Area | 1.5–2.2 m² per panel | Project design dependent |

| Expected Lifespan | 15–25 Years | Maintenance affects efficiency |

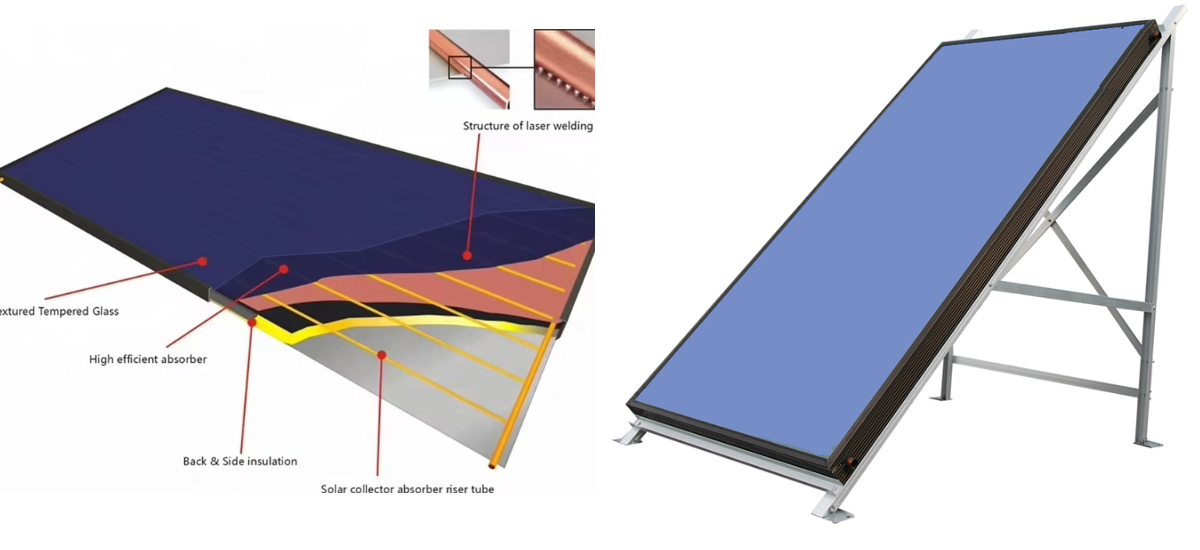

Structure & Material Composition

Absorber Plate:Aluminum/copper sheet with selective coating

Transparent Cover:Low-iron tempered glass for higher transmittance

Heat Pipes / Copper Tubes:High thermal conductivity circulation

Insulation Layer:Glass wool / polyurethane to reduce heat loss

Frame:Anti-corrosion aluminum or galvanized steel

Mounting System:Wind and snow load certified structure

Manufacturing Process

Material preparation & surface cleaning

Selective absorber coating using vacuum sputtering or oxidation

Copper tube-welding and bonding to absorber plate

Glass cutting & sealing under high temperature

Frame assembly with weatherproof sealing

Fluid pressure testing & thermal performance inspection

Packaging with anti-vibration protection

Industry-Type Comparison

| Category | Solar Thermal Collector System | Electric Water Heating | Gas Boiler |

|---|---|---|---|

| Energy Consumption | Free solar energy | High electricity cost | Depends on gas price |

| Carbon Emissions | Zero during operation | Medium | High |

| Operating Cost | Lowest (maintenance only) | High | Medium |

| Temperature Level | Medium–High | High | High |

| System Lifespan | 15–25 years | 8–15 years | 10–15 years |

Application Scenarios

Solar hot water for hotels, hospitals, schools

Process heating for food, textile, chemical plants

District heating integration for residential blocks

Swimming pools and recreation centers thermal supplies

EPC projects for renewable energy compliance

Key Pain Points & Solutions

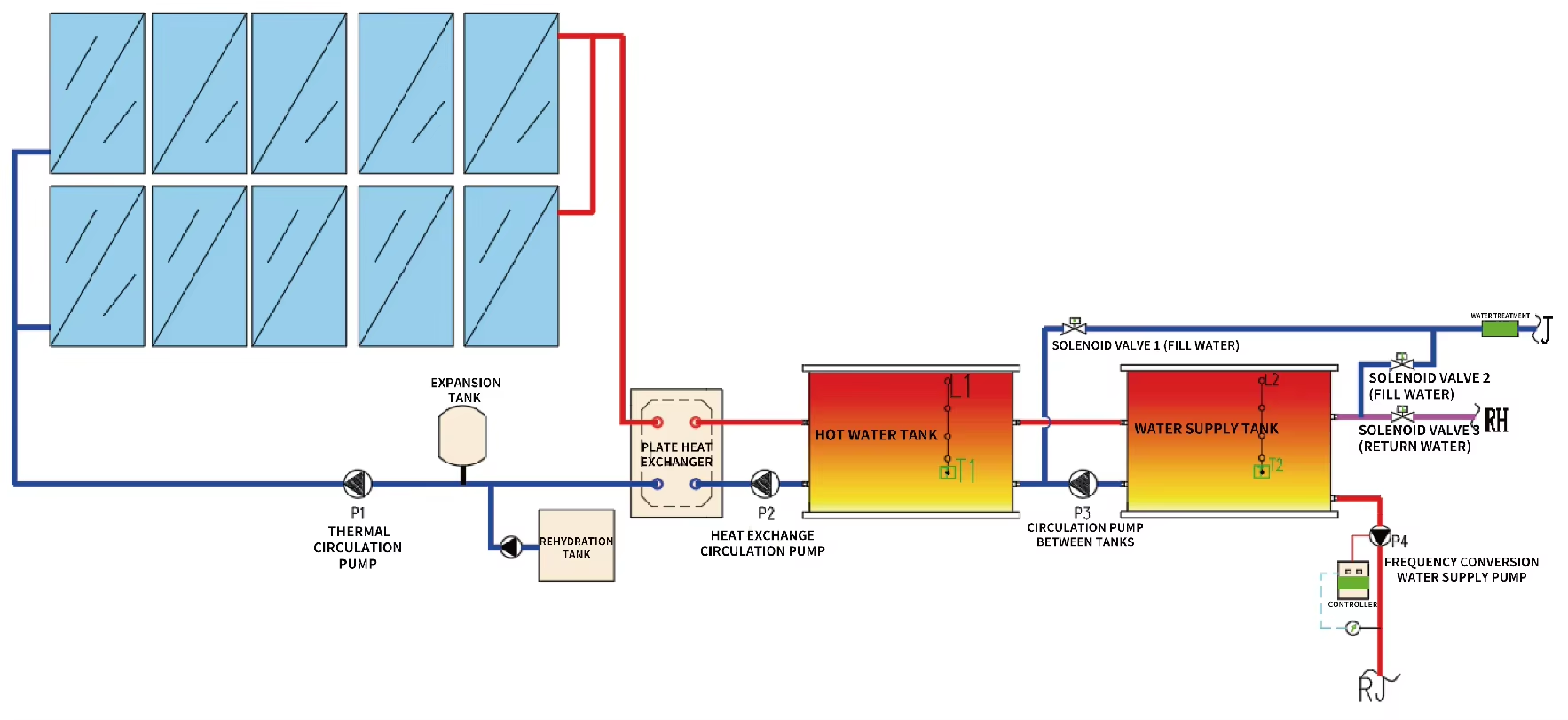

Low winter performance → Hybrid integration with auxiliary heating unit improves seasonal stability

Heat loss in long piping → Industrial-grade insulation and minimized routing design

Scaling and corrosion risk → Closed-loop glycol system with water treatment

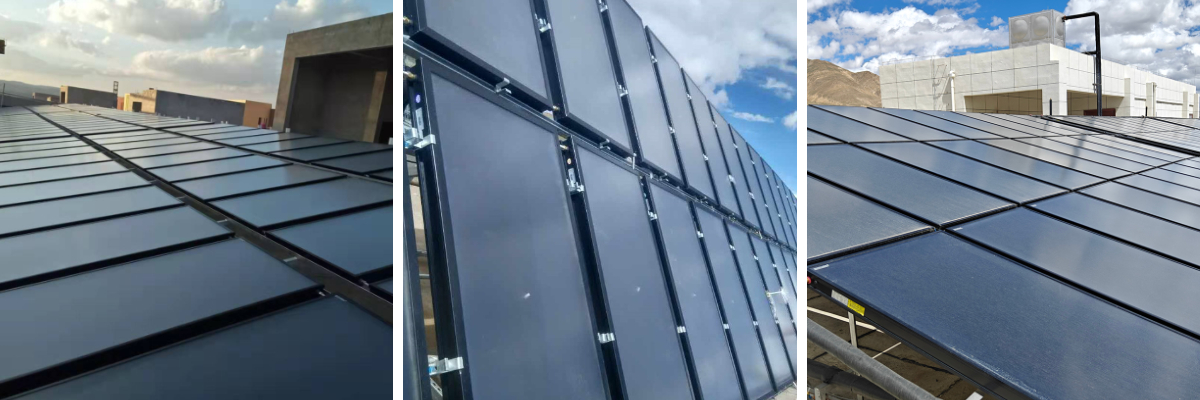

Unstable installation conditions → Wind/snow load certified structure and finite element verified mounting

Risk Warnings & Mitigation

Avoid stagnation by adding temperature control valves and real-time monitoring

Use antifreeze fluid for climate below 0°C

Inspect seals and joints annually to prevent leakage

Ensure local fire and building code compliance

Procurement & Selection Guide

Confirm required thermal load and annual solar resource data

Select collector type (flat / evacuated tube) per temperature demand

Calculate panel area based on efficiency and roof structure

Evaluate certifications: CE, Solar Keymark, ISO 9806

Check heat exchanger and controller compatibility

Assess supplier delivery capacity and after-sales plan

Inspect sample reports and third-party performance testing

Engineering Case Example

A commercial hotel (180 rooms) installed 300 m² solar thermal collector system providing 60°C hot water for guestrooms and kitchen. The system covered 65% annual heating demand, reducing operating cost by 38% and cutting CO₂ emissions by 92 tons per year. The project successfully passed performance verification after six months of operation.

FAQ

Q: Typical payback period?

A: 3–6 years depending on energy prices.Q: Can the system run at night?

A: Heat is stored in insulated tanks for night use.Q: Suitable for industrial process heat?

A: Yes, up to 180°C with vacuum tube collectors.Q: Roof direction requirements?

A: South-facing with tilt angles 20–40° recommended.Q: Storm resistance?

A: Designed with wind/snow load certificates per region.Q: Water quality concerns?

A: Closed-loop circulation protects collector from scaling.Q: Lifespan of glass cover?

A: 15+ years with anti-impact tempered glass.Q: Can integrate into existing hot water system?

A: Fully compatible with boilers for hybrid setup.Q: Warranty length?

A: Typically 5–10 years for collectors.Q: Maintenance frequency?

A: Annual inspection recommended.

Request Pricing & Technical Documentation

Contact the engineering team for RFQ, installation drawings, performance datasheet, and sample project analysis. Professional support available for EPC bids and facility retrofits.

Author Qualification — E-E-A-T Verified

The article is written by a senior renewable energy technical consultant with more than 10 years of experience in commercial solar heating system design, covering manufacturing audits, system simulation, and international project delivery across the Middle East, Southeast Asia, and Europe.

Production process:

Commitment to Sustainability: A Global Expert in Clean Heating