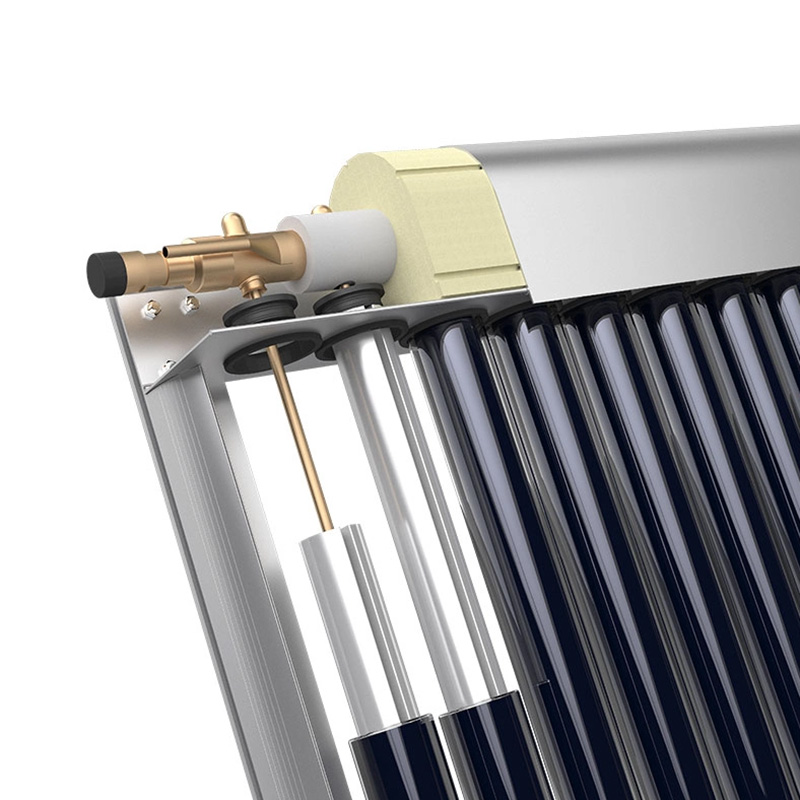

Product Introduction:

Introducing our premium Heat Pipe Vacuum Tube Solar Collector – engineered for maximum energy harvest in all climates. Each borosilicate glass tube features a vacuum-insulated chamber and high-efficiency copper heat pipe, transferring solar heat 30% faster than conventional systems even at -30°C. With specialized solar-absorbent coating (α=0.95) and dry-connect anti-freeze technology, it delivers reliable hot water for homes, pools, and industrial pre-heating. Certified to ISO 9001 & Solar Keymark standards, our modular design allows single-tube replacement and seamless integration with existing tanks. Ideal for snowy, coastal, or low-sunlight regions – achieve ROI in 2-4 years with zero operational downtime.

![Solar Collector Vacuum Tube Solar Collector Vacuum Tube]()

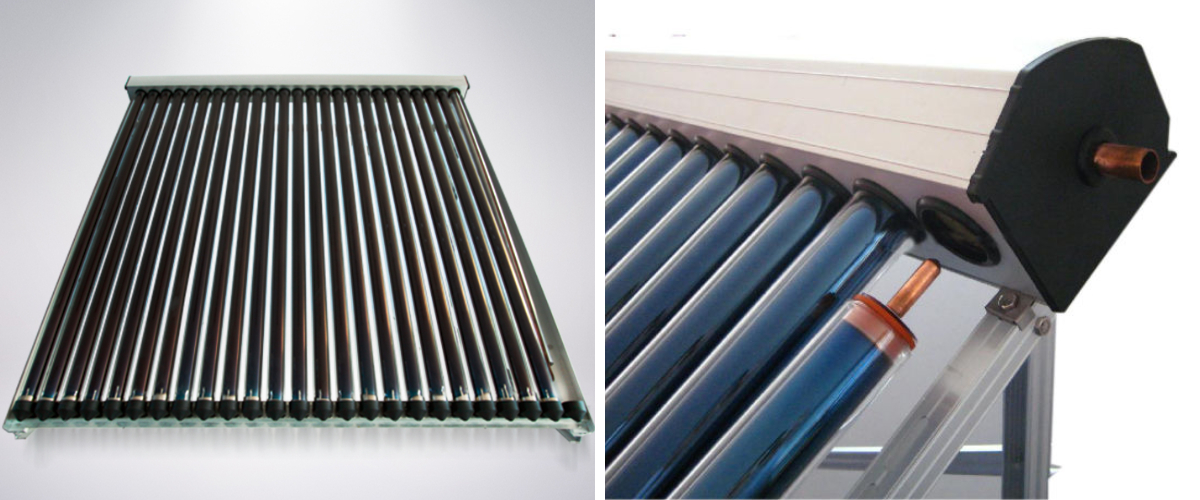

Technical Parameters:

High-Efficiency Heat Pipe Solar Collector Vacuum Tube.

Collector model | HPC318 | HPC395 | HPC472 |

Dimensions(mm) | 1720×1936×156 | 2120×1936×156 | 2520×1936×156 |

Vacuum Tube Specifications | φ58×1800 | φ58×1800 | φ58×1800 |

Vacuum Tube Quantity | 20 | 25 | 30 |

Contour area(m²) | 3.18 | 3.95 | 4.72 |

Heat collecting area(m²) | 2.00 | 2.50 | 3.00 |

Net weight(kg) | 70 | 88 | 104 |

Working pressure(MPa) | 0.6MPa |

Interface size | G3/4 external thread |

Number of interfaces | 2 |

Total heat loss coefficien | 2.453W/(m² ·K) |

Maximum working temperature(℃) | 120℃ |

Peak efficiency | 0.724 | 0.724 | 0.724 |

Rated efficiency① | 0.6 | 0.6 | 0.6 |

Rated power(kW)② | 400W/m² | 0.33 | 0.42 | 0.50 |

700W/m² | 0.77 | 0.96 | 1.65 |

1000W/m² | 1.20 | 1.50 | 1.80 |

Working fluid capacity(L) | 1.35 | 1.67 | 1.98 |

Note:

(1) Rated efficiency:The total irradiance on the daylighting surface of the collector is 1000W/m²,and the temperature difference between the average temperature of the collector and the ambient air temperature is 50℃.Calculate the efficiency value of the solar collector according to the instantaneous efficiency equation of the collector's daylighting area.

(2) Rated power:The total irradiance of the collector lighting plane is 1000w/m²,and the collector power when the temperature difference between the average collector temperature and the ambient air temperature is 50°C is equal to the product of the rated efficiency and theday lighting area and 1000W/m² .

![Solar Collector Vacuum Tube Collector Solar Collector Vacuum Tube Collector]()

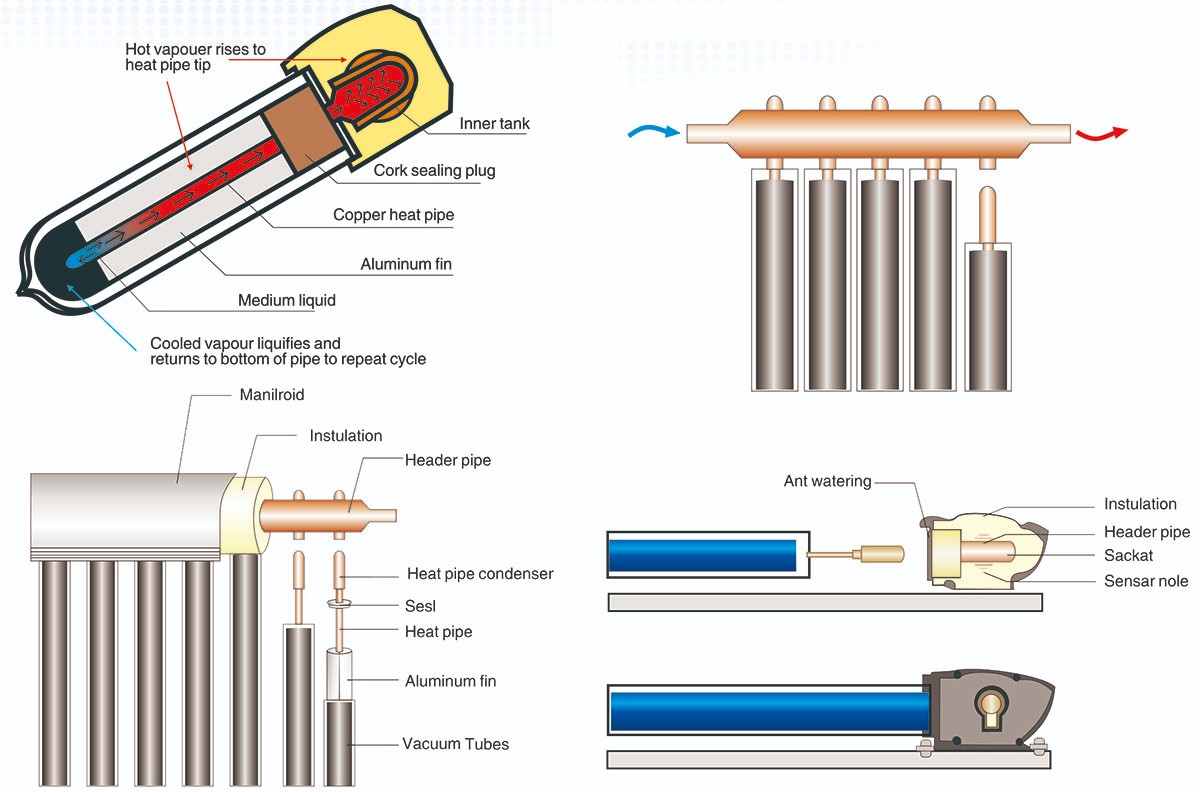

Working Principle of Heat Pipe Vacuum Tube Solar Collector:

✅ Solar Absorption: Sunlight passes through the outer borosilicate glass tube (94%+ transparency) and strikes the aluminum absorber fin coated with a selective solar-absorbing layer.

✅ Vacuum Insulation: The evacuated space between the inner and outer glass tubes eliminates convective/conductive heat loss, trapping >95% of absorbed heat.

✅ Heat Pipe Phase-Change Transfer: The absorber heats the sealed copper heat pipe attached to the fin.

✅ Condensation & Heat Release: Vapor condenses at the copper condenser bulb (top manifold contact point), releasing latent heat to the heat-transfer fluid (glycol/water) in the manifold.

✅ Dry-Connection System: Heat pipes insert into the manifold via copper sleeves – no fluid enters the tubes. Eliminates freeze/leak risks and enables single-tube replacement.

![Solar Collector Vacuum Tube Solar Collector Vacuum Tube]()

Technical Advantages:

Key Tech Advantages Enabled by This Principle

✅ Extreme Cold Operation

Phase-change fluid activates at low temps (works at -30°C).

✅ Zero-Stagnation Damage

Heat pipe "switches off" when manifold fluid reaches set temp.

✅ Angular Flexibility

Heat pipes transfer heat at 15°–90° tilt (no direct sun alignment needed).

![Solar Collector Vacuum Tube Solar Collector Vacuum Tube]()

Residential Applications:

Solar evacuated tube collector for cold climates, scale resistant heat pipes, high efficiency vacuum tube collector.

🏡 1. Residential Hot Water & Heating

Scenario: Single-family homes, apartments, off-grid cabins in cold/snowy regions.

🏊 2. Commercial Pool/Spa Heating

Scenario: Hotels, gyms, public pools (40–60°C required).

🏭 3. Industrial Process Pre-Heating

Scenario: Food processing, textiles, breweries (70–90°C feedwater).

⚡ 4. Hybrid Solar Combisystems

Scenario: District heating networks, schools, hospitals.

❄️ Best for: Cold regions, hard water zones, and pressure-critical installations.

![Solar Collector Vacuum Tube Solar Collector Vacuum Tube]()

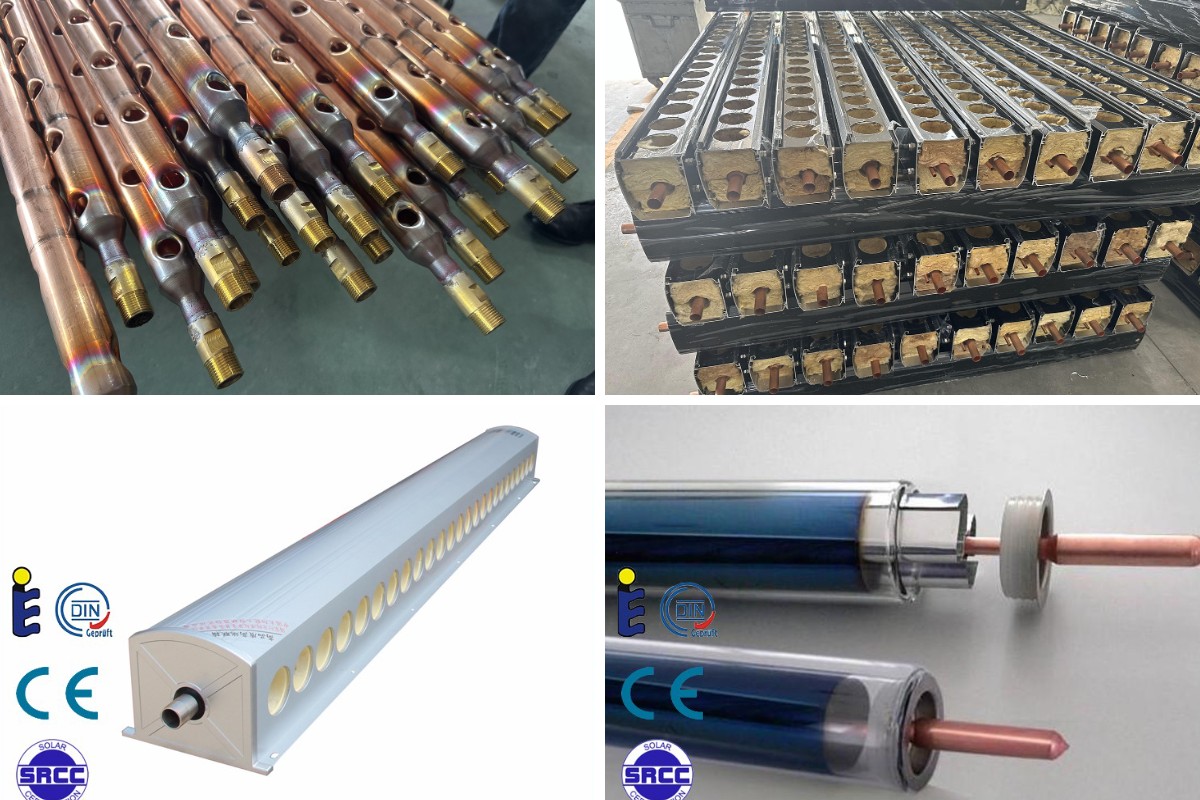

Production Process:

![Solar Collector Vacuum Tube Solar Collector Vacuum Tube]()

Q1: What is a heat pipe solar collector?

A1: A heat pipe solar collector uses evacuated glass tubes with sealed copper pipes to efficiently transfer solar heat to a circulating fluid. It's known for its fast start-up, high efficiency, and excellent performance in cold climates.

Q2: How does a heat pipe work in solar collectors?

A2: The heat pipe inside the evacuated tube contains a small amount of fluid. When heated by sunlight, the fluid vaporizes and rises to the condenser end, transferring heat to the water system. The vapor then condenses and returns to the bottom, repeating the cycle.

Q3: What are the advantages of heat pipe collectors over flat plate collectors?

A3: Heat pipe collectors offer better performance in low sunlight or cold environments, faster response time, and less heat loss due to vacuum insulation. They're ideal for areas with cold winters or industrial hot water needs.

Q4: Can heat pipe collectors be used year-round?

A4: Yes. Their design with vacuum insulation and antifreeze compatibility makes them suitable for year-round operation, even in sub-zero temperatures.

Q5: What maintenance is required for heat pipe solar collectors?

A5: Maintenance is minimal. Regularly checking for leaks, cleaning the glass tubes, and inspecting the heat exchanger once a year is typically sufficient.