Heat Pipe Solar Collector

Heat Pipe Solar Collector technology remains one of the most reliable and cost-effective methods for generating low-to-medium temperature heat in commercial, industrial, and institutional environments. Its modular structure, efficient thermal transfer, and high performance under diffuse radiation make it an essential solution for factories, hospitals, residential complexes, hotels, district heating networks, and agricultural processing plants.

With rising demand for renewable heat, governments and industrial facilities increasingly adopt Heat Pipe Solar Collector systems to reduce fossil-fuel consumption and stabilize long-term operating costs. The global solar thermal market continues to expand, especially in large commercial installations, industrial pre-heating, and centralized hot-water systems, supported by programs cited by institutions such as IEA and Solar Heat Worldwide.

Concise Definition

A Heat Pipe Solar Collector is an evacuated-tube solar thermal module that transfers absorbed solar energy through sealed heat pipes into a manifold, delivering stable and efficient heat output for commercial hot-water systems, industrial process-heat applications, and large-scale renewable heating projects.

Overview and Industry Relevance

Heat Pipe Solar Collector technology remains one of the most reliable and cost-effective methods for generating low-to-medium temperature heat in commercial, industrial, and institutional environments. Its modular structure, efficient thermal transfer, and high performance under diffuse radiation make it an essential solution for factories, hospitals, residential complexes, hotels, district heating networks, and agricultural processing plants.

With rising demand for renewable heat, governments and industrial facilities increasingly adopt Heat Pipe Solar Collector systems to reduce fossil-fuel consumption and stabilize long-term operating costs. The global solar thermal market continues to expand, especially in large commercial installations, industrial pre-heating, and centralized hot-water systems, supported by programs cited by institutions such as IEA and Solar Heat Worldwide.

Technical Specifications

Technical parameters below represent common specifications required for engineering design and procurement:

• Tube type: double-glass evacuated tube

• Tube length: 1500–1800 mm

• Tube outer diameter: 58–70 mm

• Heat pipe material: copper, selective coating absorber

• Gross thermal output: 0.8–1.6 kW per tube (at 1000 W/m²)

• Optical efficiency (η₀): 65%–78%

• Stagnation temperature: 180–250°C

• Recommended working pressure: 0.6–1.2 MPa

• Manifold material: aluminum or stainless steel shell, copper header pipes

• Insulation: high-density polyurethane or mineral wool

• Expected service life: 15–25 years

Product Structure and Manufacturing Process

Core Structural Components

• Evacuated glass tubes for thermal insulation

• High-performance copper heat pipes with phase-change working fluid

• Manifold and header assembly with copper channels

• Selective absorber coating ensuring high solar absorptivity

• Aluminum frame and mounting brackets

• Thermal insulation layer to reduce header heat loss

Manufacturing Workflow

1) Raw materials preparation and glass tube forming.

2) High-vacuum creation and sealing of evacuated tubes.

3) Selective absorber coating application using sputtering or chemical deposition.

4) Heat pipe charging, vacuum sealing, ultrasonic testing, and thermal validation.

5) CNC cutting and welding of manifold headers.

6) Assembly of tubes, manifold, insulation, and casing.

7) Pressure testing, thermal performance testing, and quality-assurance documentation.

8) Packaging, palletizing, and shipment with installation manuals.

Engineering Calculation Example

Objective: Estimate annual thermal output for a Heat Pipe Solar Collector field serving an industrial pre-heating system.

Step 1 — Determine gross collector area: assume 450 m².

Step 2 — Use peak thermal output estimate: 1.05 kW/m² gross.

Step 3 — Peak thermal capacity: 450 × 1.05 = 472.5 kW.

Step 4 — Use local equivalent full-sun hours: assume 950 h/year.

Step 5 — Annual energy yield: 472.5 × 950 = 449,875 kWh/year.

Step 6 — Deduct 18% system losses (pumps, piping, exchanger): net ≈ 368,900 kWh/year.

This calculation method is widely used by EPC engineers to compare system proposals and determine levelized cost of heat.

Market Trends and Data

Industry reports from organizations such as IEA and Solar Heat Worldwide indicate continuous growth in solar thermal deployment for industrial and commercial applications. Large centralized systems, district heating pre-heating arrays, and industrial process-heat retrofits represent the strongest demand segments. More than 500 GWth of solar thermal capacity is already installed worldwide, showing steady long-term relevance and proving the viability of Heat Pipe Solar Collector systems in various climates.

Application Scenarios

An industrial laundry facility installed a 380 m² Heat Pipe Solar Collector field designed for 65°C pre-heating. After commissioning, the system delivered approximately 275 MWh/year of usable heat, reducing diesel boiler consumption by 38% and cutting annual operating expenses significantly. The modular design enabled rapid maintenance through individual tube replacement without interrupting full system operation.

Industry Comparison Table

| Category | Heat Pipe Solar Collector | Flat Plate Collector | ETC U-Pipe Collector |

|---|---|---|---|

| Thermal Efficiency | High | Medium | Medium-High |

| Diffuse Light Performance | Excellent | Poor | Moderate |

| Operating Temperature | Up to 250°C | Up to 120°C | Up to 180°C |

| Maintenance | Low, modular tubes | Low | Moderate |

| Best Use Case | Commercial & industrial heat | Domestic hot water | Small commercial systems |

Risk Alerts and Solutions

Risk: Vacuum degradation in tubes.

Solution: Use tubes with certified long-term vacuum retention and maintain spare tubes onsite for rapid swap-out.

Risk: Corrosion or freezing of heat-transfer fluids.

Solution: Use glycol mixtures rated for extreme ambient temperatures and ensure material compatibility for all metals.

Risk: Underperformance versus design expectations.

Solution: Require verified test reports, thermal curves, and on-site performance acceptance testing.

Risk: Overheating during stagnation periods.

Solution: Integrate temperature relief valves, proper circulation control, and adequate buffer storage volume.

Selection Guide

1) Define temperature and daily load requirements with precision.

2) Request complete thermal performance curves and independent validation reports.

3) Verify tube specifications: glass thickness, coating type, and vacuum life guarantee.

4) Confirm manifold material quality and insulation density for long-term durability.

5) Evaluate supplier experience in commercial and industrial projects, not only residential products.

6) Assess installation method, mounting structure strength, and local wind/snow considerations.

7) Compare long-term operating cost using standard heat-cost modeling.

8) Require support for commissioning, O&M training, and spare parts supply.

Glossary of Engineering Terms

Aperture Area: Active solar-receiving surface of the collector.

Stagnation Temperature: Maximum temperature under no-load conditions.

Glycol Mixture: Freeze-protected heat-transfer fluid.

Selective Coating: High-absorptance, low-emittance surface on absorber tube.

Header Manifold: The chamber collecting heat from multiple heat pipes.

FAQ

Q1: What temperature range can a Heat Pipe Solar Collector achieve?

A1: Typically 60–250°C depending on tube design, manifold construction, and system integration.

Q2: How does a heat pipe improve efficiency?

A2: Phase-change fluid inside the heat pipe rapidly transfers heat with minimal loss, improving performance under low radiation.

Q3: Can it operate in cold climates?

A3: Yes, evacuated tubes maintain internal vacuum insulation, and glycol mixtures prevent freezing.

Q4: How long do evacuated tubes last?

A4: Most high-quality tubes last 15–25 years; vacuum loss is rare with reliable manufacturing.

Q5: How often is maintenance required?

A5: Only periodic tube inspection and fluid replacement every few years, depending on system size.

Q6: Can individual tubes be replaced?

A6: Yes, modular replacement is one of the key advantages of Heat Pipe Solar Collector systems.

Q7: Is it suitable for industrial process heat?

A7: Yes, especially for low-to-medium temperature pre-heating up to 250°C.

Q8: What is the typical payback period?

A8: Commercial projects generally achieve payback within 3–6 years depending on fuel costs.

Q9: Can it integrate with thermal storage?

A9: Yes, integration with insulated tanks significantly improves system stability and output.

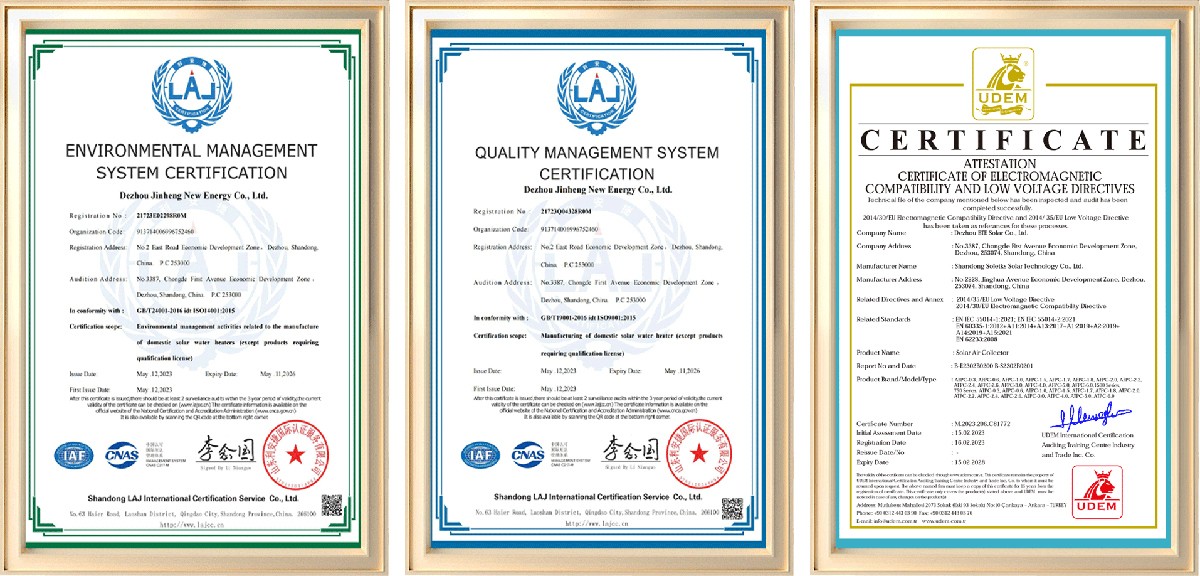

Q10: What certifications should buyers check?

A10: Certifications related to thermal performance, pressure safety, material quality, and vacuum integrity.

Commercial CTA

For bulk procurement, OEM partnerships, or turnkey system integration using Heat Pipe Solar Collector technology, contact our commercial engineering team for detailed quotations, thermal simulations, and project-specific system designs. We support wholesalers, EPC contractors, and government procurement agencies with technical drawings, performance models, and fast production lead times.

Author Information

Written by a Senior Solar Thermal Engineer with 16 years of experience in industrial heat system design, collector manufacturing, and EPC project delivery. Technical background includes large-scale commercial renewable-heat integration across multiple regions.

Referenced institutions: IEA, Solar Heat Worldwide.

Honors and Qualifications: