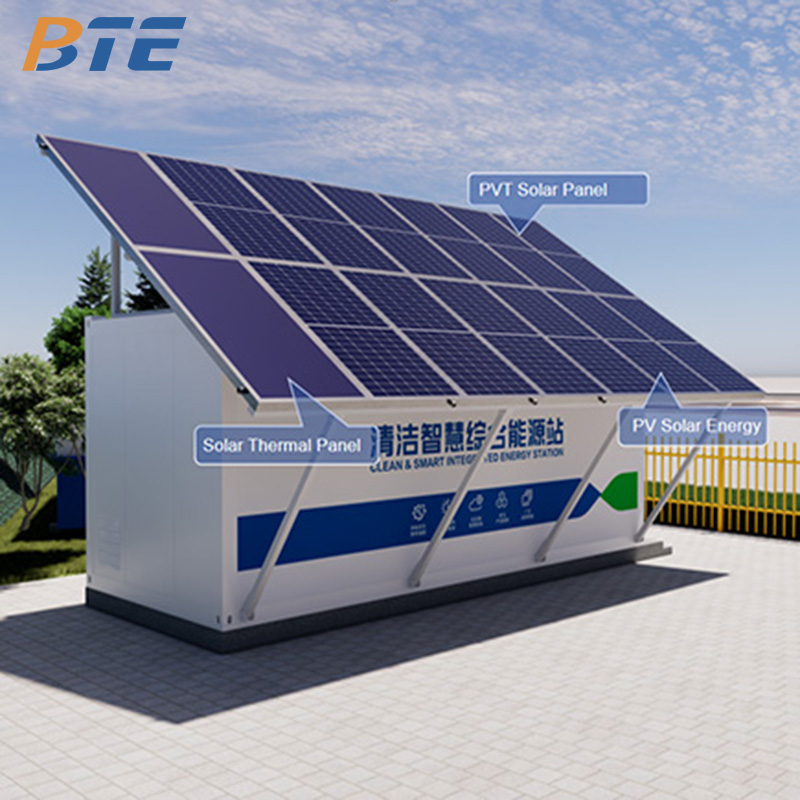

PVT Solar Panels

PVT Photovoltaic Thermal Module

1. Dual Function:Generates electricity and collects heat in one module.

2. High Efficiency:Total energy conversion efficiency exceeds 70%.

3. Space-Saving:One system meets both power and heating needs.

4. Durable & Reliable:Excellent insulation, weather resistance, and long lifespan.

Product Introduction:

The PVT Photovoltaic Thermal Module is an advanced solar solution that combines photovoltaic power generation with efficient thermal energy collection in a single system. Unlike traditional solar panels that only generate electricity, our PVT modules also capture and utilize heat energy, simultaneously meeting the demand for electricity, hot water, and space heating.

With patented full-flow channel technology and lamination without hidden cracks technology, our modules increase power generation efficiency by 8–15% while achieving a comprehensive conversion efficiency of over 70%. This means more energy output per square meter, reduced system losses, and maximum utilization of solar resources.

Product Features

PVT photovoltaic thermal modules integrate power generation and heat collection into a highly efficient integrated system.

Technical Parameters:

Specification of PVT

Item | Liquid circulation | Liquid circulation | liquid circulation | |

Dimension(mm) | 2279×1134×37 | 2279×1134×37 | 1762×1134×37 | |

Dimension of Glass (mm) | 2273×1128 | 2273×1128 | 1756×1128 | |

Weight(kg) | 39.0 | 39.0 | 34.6 | |

Electricity | Peak Rate/W | 580 | 540 | 450 |

Component type | Single crystal/multiple main gate/N type TOPCon | Single crystal/multiple main gate /P type PERC | Single crystal/multiple main gate /N type TOPCon | |

Component structure | 144(6×24)cells | 144(6×24)cells | 108(6×18)cells | |

Operating Temperature /℃ | -40~85 | -40~85 | -40~85 | |

Max system voltage/V | 1500V(TUV) | 1500V(TUV) | 1500V(TUV) | |

Open Circuit voltage (Voc)/V | 51.1 | 49.73 | 39.78 | |

Max power point operating voltage (Vmp)/V | 44.45 | 41.13 | 33.21 | |

Short Circuit Current (Isc)/A | 14.31 | 13.89 | 14.00 | |

Max power operating current (Imp)/A | 13.05 | 13.13 | 13.55 | |

Module efficiency | 22.44% | 20.9% | 22.5% | |

Thermal | Thermal peak efficiency(W) | 1180 | 1180 | 910 |

liquid capacity(L) | 1.2 | 1.2 | 0.95 | |

Medium type | Propylene glycol /glycol /water | |||

Work pressure(MPa) | 0.6 | |||

How it works | Indirect expansion type | |||

Interface /Quantity | G1/2 male thread / 2 | G1/2 male thread / 2 | G1/2 male thread / 2 | |

Heat transfer structure | Tube plate | Tube plate | Tube plate | |

Heat transfer material | Red copper | Red copper | Red copper | |

Back sheet material | Color-coated sheet | Color-coated sheet | Color-coated sheet | |

Quantity for 40HQ | 28 pcs/pallet,560pcs/40HQ | 28 pcs/pallet,560pcs/40HQ | 28 pcs/pallet,700pcs/40HQ | |

Application Scenario | Low temperature radiant heating/pool heating/interseasonal heat storage/Combined with heat pump | |||

Remark:

1. Integrated, high income: photoelectric, photothermal integrated coupling design, make full use of solar energy resources, the same area of more income.

2. Reliable and long life: reduce the working temperature of the surface of the solar module, improve the working condition, extend the service life and obtain more power generation

3. Precision, high performance: The use of half a single crystal multi-main gate N-type TOPCon battery, partition temperature and no hidden crack laminated heat transfer process, close-packed heat exchange runner layout, two EL detection, two air tightness detection, one insulation resistance test, excellent process stability.

Advantages of PVT (Photovoltaic-Thermal) Modules:

PVT Lamination: No Microcracks: Our unique single-piece lamination process ensures that the module and heat exchange backsheet are formed in one go, guaranteeing microcrack-free photovoltaic silicon cells.

Microcrack-Free PVT System Operation: PVT modules are composed of materials with diverse characteristics, such as glass panels, aluminum alloy frames, full-channel heat exchange backsheets, and silicon cells. These systems operate daily in ambient temperatures ranging from -40°C to 80°C. Our products effectively overcome the challenges posed by the thermal expansion stability of these different materials and potential module deformation during system operation, ensuring that the photovoltaic silicon cells will not develop microcracks under operating conditions.

Proprietary Full-channel Heat Exchange Backsheet: The flow channel design within the core of our full-channel flat-plate collector is optimized based on fluid dynamics principles and is formed flexibly using a one-shot molding process. It features integrated heat absorption and heat exchange, rapid circulation, low thermal resistance, high heat transfer efficiency, hydraulically balanced parallel flow channels, and uniform flow distribution. The entire plate simultaneously collects and transfers heat, achieving 100% thermal contact between the absorber and the heat transfer fluid. The heat transfer area is 2.2 times the aperture area, representing the highest heat collection and transfer ratio and excellent thermal conductivity in the global solar thermal industry.

Superior Weather Resistance: The full-channel heat transfer base plate utilizes ultra-pure ferritic stainless steel specifically developed for water-based applications. It boasts high thermal conductivity, excellent stability, ductility, toughness, high wear resistance, high fatigue strength, high temperature resistance, corrosion resistance, and oxidation resistance. It maintains its original structure even at temperatures exceeding 200°C, resulting in a service life of up to 25 years, matching the lifespan of the photovoltaic module.

Product Applications

Because PVT (photovoltaic-thermal) hybrid solar modules fully utilize solar energy with an efficiency of up to 92%, providing both electricity and heat, they are suitable for a wide range of applications:

Residential Buildings

They simultaneously provide electricity, domestic hot water, and heating for homes with limited roof space, such as villas, apartments, and rural residences, achieving efficient energy utilization.

Commercial and Industrial Buildings and Public Institutions

They provide centralized hot water, electricity, and heating for hotels, office buildings, hospitals, schools, nursing homes, shopping malls, and government buildings, reducing energy costs and achieving efficient use of green energy.

Industrial Plants

They meet the continuous demand for process heat and electricity in environments such as light industry, food processing, textiles, and workshops, and are particularly suitable for production environments with stable heat and electricity loads.

Agricultural Greenhouses

PVT cogeneration systems help maintain stable indoor temperatures, promote crop yields, and reduce reliance on traditional fossil fuels.

Multi-Energy Complementary System

PVT, as a component, can be flexibly integrated with heat pumps, air-source systems, biomass boilers, thermal or electrical storage devices, and other technologies to build a diversified and coordinated energy supply system.

PVT Application Scenarios and Schematic Diagram

PVT Thermal/Electric Energy System

After the PVT photovoltaic thermal module collects heat, the temperature at the T1 sensor probe increases. When the T1 temperature exceeds T2, the control instrument starts the circulation pump. The circulation pump circulates the medium and transfers heat to the hot water storage tank. The system uses a pressure-driven mechanism to open the hot water valve. When hot water flows out, cold water is automatically replenished. The PVT system can generate electricity for self-use or connect to the grid.

Quality Certifications

At Shanke Lanxin, product quality and reliability are our top priorities. All of our PVT photovoltaic thermal modules and solar thermal systems are manufactured in strict accordance with international standards. We have received numerous quality certifications from recognized third-party organizations to ensure product safety, performance, and long-term durability.

Our certifications include:

ISO 9001 – Quality Management System

ISO 14001 – Environmental Management System

ISO 45001 – Occupational Health and Safety

CE Certification – Compliant with European Standards

These certifications demonstrate our commitment to excellence and give our global partners confidence in every product produced in our factories.

Service Commitment

At BTE Solar, we are committed not only to providing high-performance solar products but also to providing exceptional service at every stage of our relationship.

Pre-sales Consultation

We offer customized system design advice and technical support based on your specific project requirements.

On-Time Delivery

With strong production capacity and extensive inventory, we ensure timely delivery of both standard and custom orders.

Quality Assurance

All products undergo rigorous quality control and are certified to meet international standards.

After-sales Support

We provide technical guidance, system maintenance advice, and rapid response services to ensure long-term system stability.

Customer First

We value our partnerships with every customer and strive to build long-term relationships based on trust, transparency, and satisfaction.

BTESolar is your reliable partner for sustainable, efficient, and worry-free solar solutions.