High Efficiency Solar Collector Tube

The global demand for the High Efficiency Solar Collector Tube continues to expand as industries pursue cost-effective and low-carbon heating solutions. According to recent international energy reports, solar thermal applications have grown steadily across Asia-Pacific, Europe, and Latin America. This trend is driven by policy incentives, rising natural gas prices, and higher expectations for system performance.

As commercial and industrial facilities increase the adoption of solar thermal systems, the High Efficiency Solar Collector Tube has become a critical component for achieving stable heat output, long operational life, and reduced levelized cost of energy.

Global Market Landscape for High Efficiency Solar Collector Tube

The global demand for the High Efficiency Solar Collector Tube continues to expand as industries pursue cost-effective and low-carbon heating solutions. According to recent international energy reports, solar thermal applications have grown steadily across Asia-Pacific, Europe, and Latin America. This trend is driven by policy incentives, rising natural gas prices, and higher expectations for system performance.

As commercial and industrial facilities increase the adoption of solar thermal systems, the High Efficiency Solar Collector Tube has become a critical component for achieving stable heat output, long operational life, and reduced levelized cost of energy.

Industry Data & Emerging Trends

Global installations of evacuated solar collector systems have surpassed tens of millions of square meters, with growth led by industrial hot water, district heating, agricultural drying, and solar-assisted manufacturing. High Efficiency Solar Collector Tube technology is favored due to its excellent heat retention and ability to operate effectively in low-temperature and high-wind environments.

Recent market analyses highlight several notable trends:

1. Rapid transition from standard vacuum tubes to selective-coating High Efficiency Solar Collector Tube models.

2. Increased demand for tubes with higher thermal efficiency, lower heat loss coefficient, and enhanced durability.

3. Adoption of automated production lines in manufacturing hubs to ensure consistent vacuum integrity.

4. Growing interest from industrial buyers in customized tube lengths, diameter variations, and optimized absorber coatings.

Technical Structure and Working Principles

The High Efficiency Solar Collector Tube commonly adopts a double-layer borosilicate glass configuration with an inner selective absorption layer. The vacuum gap between the two glass layers creates a near-zero-conduction environment, significantly reducing heat loss.

Key structural components include:

• Outer high-transmittance glass layer

• Inner absorption layer coated with aluminum-nitride or copper-oxide selective film

• Getter material for long-term vacuum stability

• Stainless-steel or glass-to-metal sealing points

This engineering enables the tube to convert solar radiation into heat with minimal reflection and maximum absorption. Compared with traditional flat-plate systems, the High Efficiency Solar Collector Tube ensures higher output even under diffuse light or low-irradiance conditions.

Core Technical Parameters

Buyers typically evaluate solar collector tubes using several performance metrics:

1. **Absorptance (α):** Usually above 93% for high-efficiency models.

2. **Emittance (ε):** Low emittance levels help preserve heat, typically ≤ 6%.

3. **Vacuum stability:** Long-term insulation performance without degradation.

4. **Thermal efficiency:** Output stability across varying climate conditions.

5. **Mechanical strength:** Impact resistance, hail resistance, and load capacity.

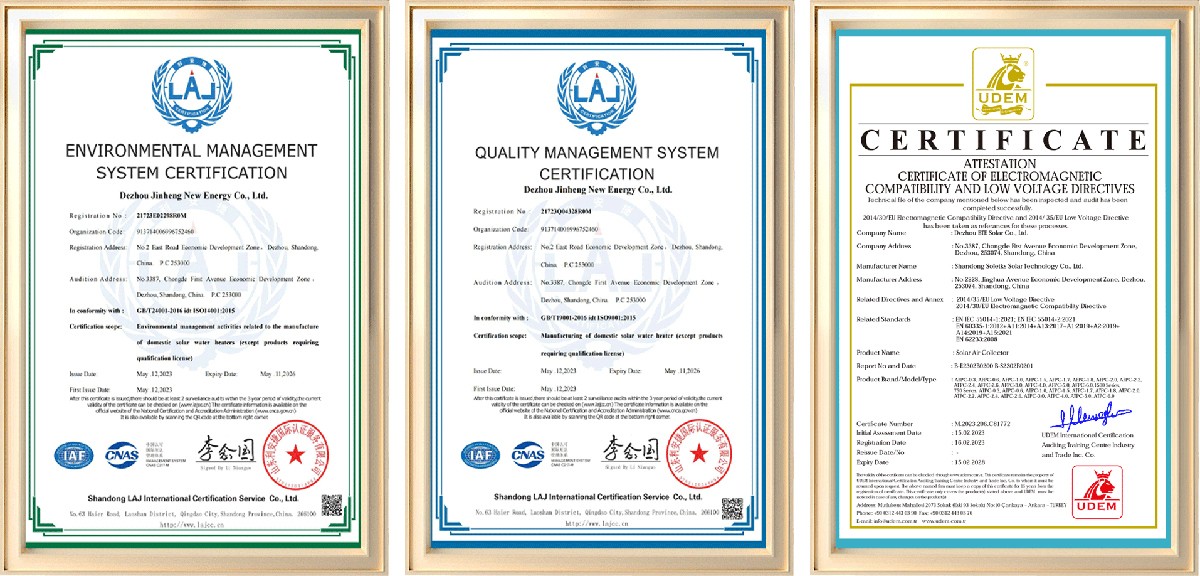

In addition to these technical indicators, international buyers increasingly request certifications such as ISO quality management, material compliance, and endurance testing reports.

Manufacturing Processes of High Efficiency Solar Collector Tube

The production process of a High Efficiency Solar Collector Tube involves precision engineering and multiple stages of quality assurance. Typical steps include:

• Selection and cleaning of borosilicate glass tubes

• Coating of the inner tube with selective absorption film

• High-temperature sealing and assembly

• Vacuum extraction and long-term sealing

• Aging tests and vacuum stability inspections

• Optical and thermal performance testing

Modern factories use automated coating equipment, precision vacuum pumps, and advanced inspection systems to ensure every High Efficiency Solar Collector Tube meets global performance and durability standards.

Applications Across Global Industries

The High Efficiency Solar Collector Tube is widely used in residential, commercial, and industrial heat generation systems. Typical applications include:

• Domestic hot water systems

• Industrial process heating

• Agricultural drying and greenhouse temperature control

• District heating networks

• Solar cooling and absorption chillers

In regions with strong solar resources, replacing conventional energy with solar thermal systems can significantly reduce operational costs and carbon emissions.

International Buyer Preferences & Procurement Pain Points

Global B2B buyers generally prioritize reliability, certification, and supplier stability when sourcing High Efficiency Solar Collector Tube components. Core expectations include:

• Consistent vacuum retention and selective coating quality

• Traceable testing data and document support

• Stable packaging to prevent glass damage during transport

• Ability to provide OEM dimensions and customized absorber coating

• Fast lead times and flexible order quantities

Common buyer pain points include uncertain product lifespan, inconsistent coating performance, incomplete technical documentation, and suppliers lacking export experience. Addressing these issues directly increases procurement confidence and long-term cooperation success.

Conclusion: Why High Efficiency Solar Collector Tube Matters for Global Markets

As global industries continue to prioritize energy efficiency and environmental sustainability, the High Efficiency Solar Collector Tube remains a core component of modern solar thermal systems. Its advanced vacuum insulation, high absorption rate, and strong adaptability make it indispensable for industrial heating, commercial hot water systems, and long-term renewable energy planning.

International buyers seeking stable quality, verified performance, and long-term supply reliability should consider requesting detailed specifications, sample testing, and engineering consultations to ensure optimal system performance.

FAQ

1. What is the lifespan of a High Efficiency Solar Collector Tube?

Quality tubes generally last 15–25 years depending on coating stability and vacuum retention.

2. Can the tubes operate in cold or high-wind conditions?

Yes. The vacuum layer provides excellent insulation, and selective coatings maintain heat output even in low-irradiance seasons.

3. How should buyers evaluate tube quality before ordering?

Request thermal efficiency data, vacuum stability reports, hail-resistance tests, and coating uniformity documentation.

4. Do suppliers support OEM customization?

Most professional manufacturers support customized tube lengths, diameters, absorber coatings, and performance parameters.

Professional Call-to-Action

For detailed specifications, engineering drawings, quotation support, or sample evaluation of the High Efficiency Solar Collector Tube, you may contact our technical sales team. We provide comprehensive guidance for project sizing, system design, and procurement planning.

Reference Notes

• Data referenced from international solar thermal industry reports and global renewable energy statistical yearbooks.

• Technical indicators derived from common industry testing standards and laboratory performance evaluations.

Honors and Qualifications: