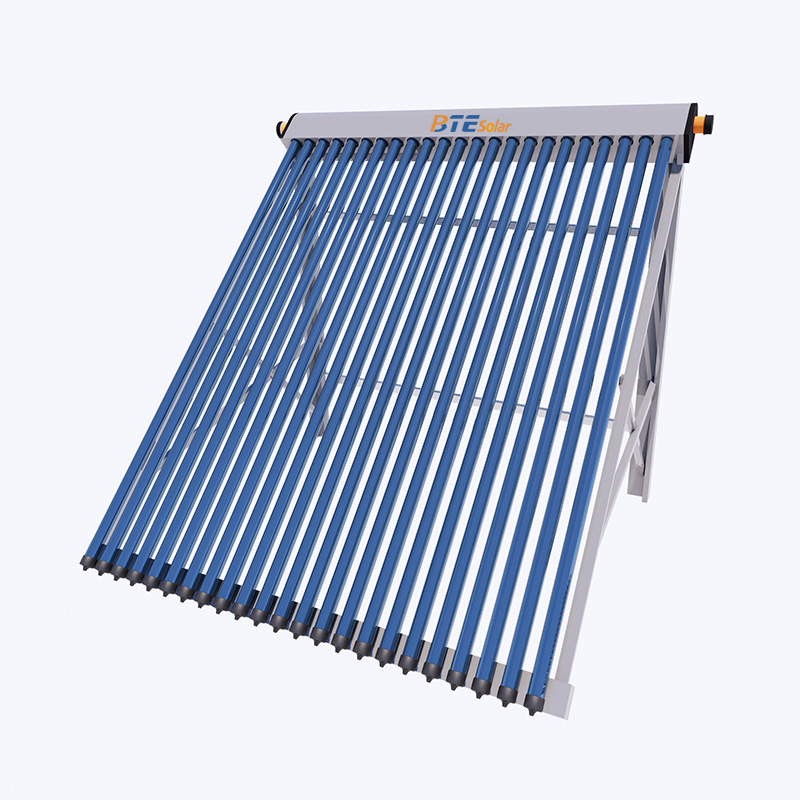

Split Presurized Solar Water Heater

Key Advantages:

1. Year-Round Performance: Vacuum tubes absorb solar energy even in cloudy weather or sub-zero temperatures (-25°C to -30°C).

2. High-Pressure Output: Integrates seamlessly with existing plumbing for strong shower flow.

3. Anti-Freeze Technology: Heat pipes prevent freezing without glycol additives.

4. Space-Saving & Aesthetic: Compact roof footprint; storage tank installed indoors/out of sight.

5. Low Maintenance: Self-cleaning tubes & corrosion-resistant materials.

6. Energy Savings: Reduce electricity/gas bills by 60–80%.

Product Overview:

Vacuum Tube Split Pressurized Solar Water Heater: Reliable & Efficient Hot Water Solution:

Our Vacuum Tube Split Pressurized Solar Water Heater harnesses solar energy to deliver high-pressure, continuous hot water for residential, commercial, and industrial use. Unlike traditional systems, its innovative split design separates the solar collector (rooftop-mounted) from the pressurized storage tank (ground/indoor installation), offering unmatched flexibility, efficiency, and frost resistance.

Parameter Table:

| Collector model | HPC318 | HPC395 | HPC472 |

Dimensions(mm) | 1720×1936×156 | 2120×1936×156 | 2520×1936×156 |

Vacuum Tube Specifications | φ58×1800 | φ58×1800 | φ58×1800 |

Vacuum Tube Quantity | 20 | 25 | 30 |

Contour area(m2 ) | 3.18 | 3.95 | 4.72 |

Heat collecting area(m2 ) | 2.00 | 2.50 | 3.00 |

Working pressure (MPa) | 0.6MPa | ||

Interface size | G3/4 external thread ×2 | ||

Total heat loss coefficien | 2.453W/(m2·K) | ||

Maximum working temperature(℃) | 120℃ | ||

Peak efficiency | 0.724 | ||

Rated efficiency | 0.724 | 0.6 | 0.724 |

Stainless Steel Water Tank:

| Model | 300 | 500 | 800 | 1000 |

Heat pipe number | 30 | 50 | 80 | 100 |

Length (mm) | 1740 | 1845 | 1720/1820 | 2000/2100 |

Inner Diameter (mm) | Φ480 | Φ580 | Φ800 | Φ800 |

Outer Diameter (mm) | Φ580 | Φ700 | Φ900/1000 | Φ900/1000 |

Insulation | PU foam 60mm | PU foam 50/100mm | ||

Inner tank material | SUS304 /SUS316 L | |||

Outer tank material | Colour-coated sheet | |||

Working pressure | 7 bar | |||

Electric heat element | 220V 1500W~3000W / 110V 1500W | |||

Coil pipe material | Optional(copper/sus304/sus316) | |||

Coil size | Φ12*1.0mm | |||

Exchange heat coil | None/Bottom coil/Upper coil and Bottom coil | |||

Expension tank | 12L | 24L | 50L | 50L |

Workstation:

Input | Pump | Rated power | Controller | Dimension | |

SR21H | AC220V/110V,50Hz | Grundfos 15-65 130 | 60-100W | SR258 | 45x30x16cm |

TSCEN-6 | AC220V/110V,50Hz | Wilo ST20/11 | 165w | FTC-6 | 27×46×16cm |

Technical Specifications & Features:

Solar Collector:

1. High-grade borosilicate glass vacuum tubes (φ58mm/φ47mm).

2. Al-N/Al selective absorption coating (≥93% absorption, ≤8% emission).

3. Heat pipe technology for rapid heat transfer.

Pressurized Storage Tank:

1. SUS304/316L stainless steel inner tank (150L–500L+ capacities).

2. Polyurethane foam insulation (50–60mm thickness).

3. Working pressure: 0.6–1.0 MPa (supports multi-point use).

System Design:

1. Split installation (collector + tank distance ≤15m).

2. Automatic temperature/pressure relief valve.

3. Compatible with electric/gas backup heaters.

Split system diagram (rooftop collector + indoor tank)

Why Choose Our System?

We combine German-engineered heat pipes, military-grade vacuum tubes, and intelligent split design to create the world’s most adaptable solar water heater. Backed by a 10-year tank warranty and 5-year tube guarantee, our systems offer payback in 3–5 years with >20-year lifespans.

Factory Advantages

1. Advanced Manufacturing: Fully automated tube production; robotic tank welding.

2. R&D Focus: Dedicated lab for thermal efficiency and pressure testing.

3. Supply Chain Strength: Vertical integration from raw materials to finished product.

4. Customization: OEM/ODM support for tank size, frame finish, and accessories.

Ideal Application Scenarios:

🏡 Residential: Villas, apartments, and homes requiring 24/7 pressurized hot water.

🏨 Commercial: Hotels, hospitals, gyms, and restaurants with high hot water demand.

🏭 Industrial: Pre-heating for manufacturing processes or laundry facilities.

❄️ Cold Climates: Reliable performance in snowy/freezing regions (e.g., Europe, Canada, mountainous areas).

International Certification:

Quality Assurance: ISO 9001, Solar Keymark, and SE certifications.

Company Introduction:

Dezhou BTE Solar Co. Ltd is mainly engaged in the export business of the Soletks group's products. It is a backbone export enterprise in the solar energy industry in Shandong Province, a key foreign trade export enterprise in Dezhou City.

There are 6 production bases and 7 branches . Now solar collector annual output can reach 3 GWh. Ranking the 3rd in the world for three consecutive years from 2017 to 2019, and the 2nd from 2020 to 2021.

BTE has always regarded technological innovation as the core competitiveness of the enterprise. It has 4 technical departments, 1 flat panel research institute.1 testing center and 1 thermal energy Institute. The scientific research personnel account for 16%, of which 50% have been in this field for more than 20 years.

At present, we has 58 core patents. Now solar collectors can use civil buildings, military facilities, industrial heating, planting, breeding, drying and other fields to provide high-quality thermal energy, heating, refrigeration, heating and other clean energy comprehensive utilization services.