✅ High Absorptance: Solar absorptance (@AM1.5) α = 95% ±2%

Solar Absorber Film

Blue Solar Absorber Film Technical Advantages:

1. α = 94% ±2%

2. High durability, wide application range

3. Great performance–cost ratio

Black Solar Absorber Film Technical Advantages:

1. α = 95% ±2%, ε = 5% ±2%

2. High efficiency, low emissions

3. Clean & continuous production

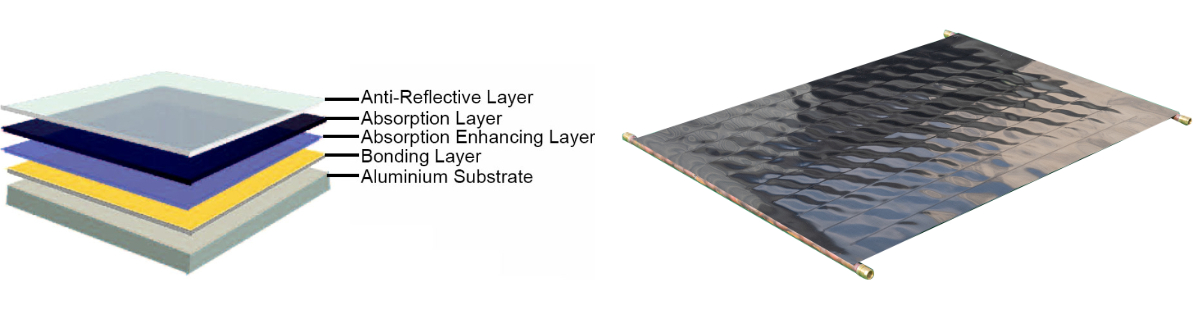

Product Description:

High-Performance Selective Solar Absorber Film for Solar Thermal Collectors

Headline: Maximize Solar Heat Harvesting: Advanced Selective Coating Film for Efficient & Durable Thermal Collectors

Unlock superior efficiency and longevity for your solar thermal collectors with our cutting-edge Selective Solar Absorber Film. Engineered with nano-technology, this specialized film is the critical component that transforms sunlight into usable heat with exceptional performance. It features an ultra-high solar absorption rate combined with extremely low thermal emittance – the hallmark of true selective surfaces.

Blue Solar Absorber Film Technical advantages:

✅ Low Emittance: Emissivity as low as 5% ±2% (@80°C)

✅ Continuous High-Efficiency Production: Delivers stable performance with high efficiency and zero pollution

Black Solar Absorber Film Technical advantages:

✅ Solar Absorptance: α = 94% ±2% (@AM1.5)

✅ Outstanding durability against weathering and salt spray, enabling wider application adaptability

✅ Cost-effective performance with reliable quality using D-DOS coating technology

Technical Parameters:

Model | Base Material | Coaing Type | Absorption ratio (%) | Emission ratio (%) |

thickness:0.3/0.4mm width:750/950/1200/1250mm Customizable | AI | Black coating film | 94±2% | 12+2% |

thickness:0.3/0.4mm width:750/950/1200/1250mm Customizable | AI | Blue coating film | 95+2% | 5+2% |

Factory & Manufacturer Advantages:

1. State-of-the-Art PVD Coating Lines: Utilizing advanced, high-throughput magnetron sputtering systems for precise, uniform, and repeatable coating deposition.

2. Rigorous Quality Control: In-line optical monitoring (absorptance/emittance measurement), comprehensive adhesion testing, and accelerated aging labs ensure batch-to-batch consi

Packaging and logistics:

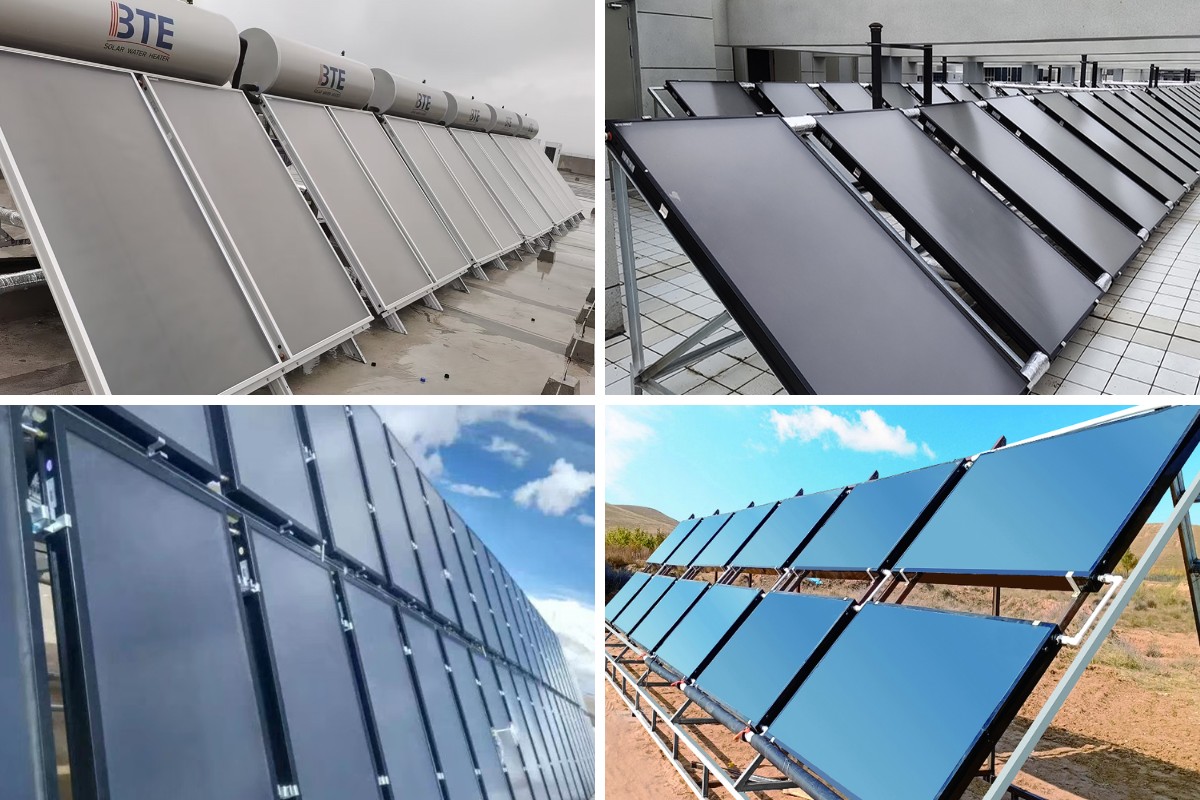

Application Scenarios:

1. Flat Plate Solar Collectors: Bonded to absorber plates (copper or aluminum) as the core heat-capturing element.

2. Evacuated Tube Collectors (ETC): Coated directly onto the inner heat pipe or U-pipe absorber fins/strips inside the vacuum tubes.

3. Unglazed Collectors (e.g., for Pool Heating): Applied to durable polymer or metal absorbers, leveraging low emittance for efficiency.

4. Concentrated Solar Thermal (CST) Receivers: (Higher-temperature grades) Used in parabolic trough or linear Fresnel receivers.

5. Industrial Process Heat (IPH): Enabling medium-temperature steam or hot water generation for manufacturing.

6. Solar Air Heating Systems: Coating absorber plates in air collectors.

7. Building-Integrated Solar Thermal (BIST): Integrated into facades or roofs where aesthetics and performance are critical.

International Certificates:

Standards Compliance: Meets or exceeds key requirements of ISO 22975-3, EN 12975 (durability tests), Solar Keymark (relevant aspects).