Manufacturing Process of Solar Absorber: A Precision Journey from Blanking to Welding

Introduction: The Core Component of Photothermal Conversion

In solar thermal utilization systems, the solar absorber serves as the core component for photothermal conversion, and its manufacturing quality directly determines the performance and lifespan of the entire system. A high-quality solar absorber must not only efficiently absorb solar energy but also possess excellent thermal conductivity and long-term durability. From raw material blanking to precision welding, each manufacturing step involves profound process technology and scientific principles.

Raw Material Preparation and Blanking Process

The manufacturing of solar absorbers begins with the selection and processing of raw materials. Current mainstream materials include metals such as copper and aluminum, with copper being the preferred choice for high-end products due to its excellent thermal conductivity. Before entering the factory, raw materials must undergo strict quality inspections, including chemical composition analysis, mechanical performance testing, and surface quality checks.

The blanking process employs high-precision CNC shearing machines or laser cutting machines to ensure dimensional accuracy within ±0.1mm. Modern production lines use automated material storage systems, with computer-controlled handling and transportation of raw materials. Special attention must be paid to the material grain direction during cutting, as this affects the quality of subsequent forming processes.

Surface pretreatment is a critical step after blanking. Alkaline degreasers remove surface oil stains, acid pickling eliminates oxidation layers, and passivation forms a protective film. Temperature, concentration, and time parameters in this process must be precisely controlled, as any deviation will affect coating adhesion.

Flow Channel Design and Forming Technology

Flow channel design represents the core technology of absorber manufacturing. Reasonable flow channel design optimizes hydrodynamic performance and improves heat exchange efficiency. Modern designs employ computational fluid dynamics (CFD) simulation technology to optimize flow channel layout and cross-sectional shape through digital.

Forming processes primarily include stamping and rolling methods. Stamping uses high-precision molds to form multiple flow channels at once in large presses. Mold design must consider material springback, typically requiring multiple trial molds and corrections to achieve ideal dimensions. Roll forming employs series of rollers for gradual forming, making it more suitable for small-batch, multi-variety production.

The latest technological development involves using 3D printing to directly manufacture absorbers with flow channels. This additive manufacturing technology enables complex flow channel structures difficult to achieve with traditional processes, such as sections and internal fins, significantly improving heat exchange efficiency.

Selective Absorption Coating Preparation

Selective absorption coating is the soul of the absorber, its performance directly determining photothermal conversion efficiency. Modern coatings use magnetron sputtering technology, where target atoms are sputtered onto the substrate surface in a vacuum environment to form nanoscale thin films.

The coating structure typically employs a graded composite design, consisting of UV-resistant layer, absorption layer, thermal conduction layer, and bonding layer from surface to interior. The UV-resistant layer uses ceramic materials such as titanium nitride, the absorption layer uses metal-ceramic composites like chromium-carbon, and the thermal conduction layer selects high thermal conductivity materials such as pure copper or silver.

The preparation process requires precise control of parameters including vacuum degree, gas ratio, sputtering power, and substrate temperature. Typically conducted in a high vacuum environment above 10-3Pa, sputtering power density must reach 2-5W/cm², with substrate temperature maintained between 150-200°C. The total coating thickness is controlled at 0.1-0.3μm, requiring 20-30 layers of different material nanofilms.

Precision Welding Process

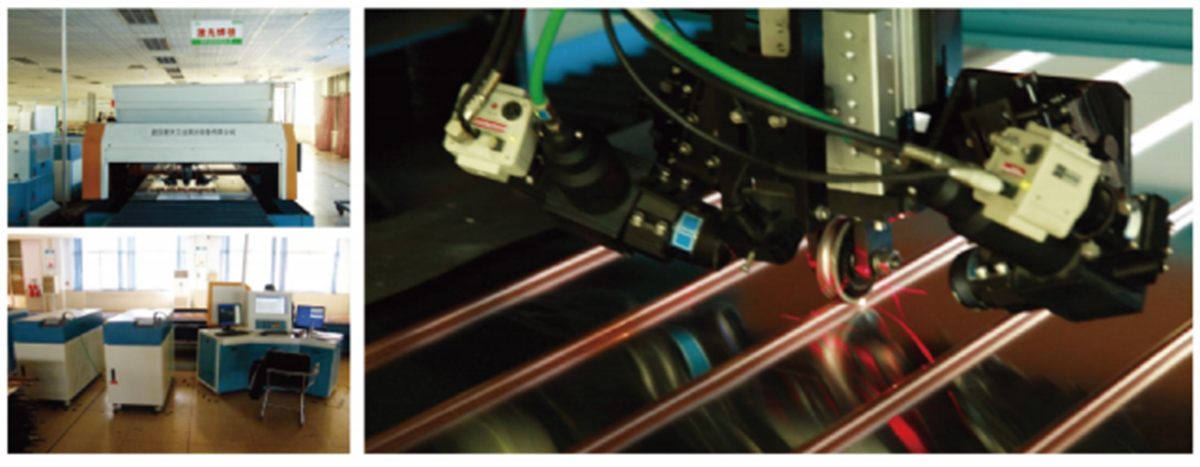

Welding is the most critical joining process in absorber manufacturing. Current mainstream technologies include ultrasonic welding and laser welding.

Ultrasonic welding uses high-frequency mechanical vibration to produce plastic deformation and diffusion bonding at metal interfaces. This solid-phase welding method does not require metal melting, avoiding corrosion problems associated with traditional brazing. Welding frequency typically ranges from 20-40kHz, amplitude is controlled at 10-50μm, and pressure is maintained at 1-3MPa. Welding time is precise to milliseconds, requiring real-time parameter adjustment based on material thickness and performance.

Laser welding employs high-energy density laser beams to achieve local melting connections. Compared to traditional welding, laser welding has a smaller heat-affected zone, less deformation, and larger weld depth-to-width ratio. Typically using fiber lasers with power ranging from 1-6kW, spot diameter of 0.2-0.6mm, and welding speeds up to 10-20m/min. Parameters such as defocus amount, shielding gas flow, and welding speed must be precisely controlled.

Weld quality inspection employs various non-destructive testing methods. X-ray detects internal defects, ultrasound examines weld integrity, and helium mass spectrometers test airtightness. Modern production lines also feature machine vision systems that monitor the welding process in real time and automatically adjust parameters.

Automated Production Line Integration

Modern absorber manufacturing employs fully automated production lines integrating robots, AGVs, and smart storage systems. Raw materials are automatically allocated through automated storage and retrieval systems, with AGVs transporting them to various workstations according to production plans.

Welding workstations use six-axis robots with visual positioning systems that automatically recognize workpiece positions and adjust welding paths. Production lines are equipped with online inspection systems, with quality monitoring points at each station enabling full-process quality traceability.

The Manufacturing Execution System (MES) coordinates the entire production process, collecting equipment status, process parameters, and quality data in real time. Big data analysis optimizes production processes, predicts equipment maintenance needs, and enables smart manufacturing and lean production.

Process Innovation and Future Development

Microchannel technology is a current research focus. Etching or diffusion welding creates microchannels with diameters of 0.1-1mm, significantly increasing specific surface area and heat exchange efficiency. However, microchannel manufacturing requires extremely high process precision and must address issues of increased flow resistance and blockage risk.

Nanofluid application represents another innovative direction. Adding nanoparticles to the working fluid significantly improves heat capacity and thermal conductivity but requires solving problems of particle settlement and corrosion. Surface modification technology can improve nanoparticle dispersion and stability.

Intelligent welding systems use artificial intelligence technology to optimize welding parameters through machine learning algorithms. The system automatically recognizes changes in material characteristics and environmental conditions, adjusting welding processes in real time to ensure weld quality stability.

Future development trends include popularization of flexible manufacturing systems enabling multi-variety, small-batch personalized production; application of digital twin technology optimizing process parameters through virtual simulation; and promotion of green manufacturing technology reducing energy consumption and waste generation.

Perfect Integration of Precision Manufacturing and Sustainable Development

The manufacturing process of solar absorbers incorporates technological achievements from multiple fields including materials science, mechanical engineering, and automatic control. Each step from blanking to welding reflects the precision and intelligence level of modern manufacturing. With continuous innovation in process technology, the performance of solar absorbers will further improve and costs will further decrease, establishing a solid foundation for popularizing renewable energy applications.

This precision manufacturing not only represents technical level but also demonstrates humanity's determination to pursue sustainable development. Each perfect weld, each precise coating layer represents an important contribution to the clean energy cause. With continuous advancement in manufacturing processes, solar thermal utilization technology will undoubtedly play an increasingly important role in energy transformation.