Beyond Efficiency: BTE Solar's Dual-Path Approach to Durable and High-Performance Solar Coatings

The Core Function Of Selective Coating: Efficient Absorption And Heat Retention

BTE Solar's Dual-Path Strategy in the Global Solar Selective Coating Market In the ever-evolving landscape of solar thermal technology, BTE Solar has emerged as a significant player, with its innovative approach to selective coatings. The global solar thermal industry, valued at over $35 billion in 2024 according to Solarico, is witnessing a continuous push for more efficient and durable systems. At the heart of this efficiency lies the selective coating, a technology that BTE Solar has mastered with its unique dual-path strategy.

The Solar Collector's Dilemma: How Selective Coatings Balance Absorption and Emittance

The Significance of Selective Coatings Selective coatings are the unsung heroes of solar collectors. Their fundamental function is to strike a balance between maximizing the absorption of solar radiation and minimizing thermal radiation losses. Absorptance (α) is a crucial parameter, and advanced coatings from BTE Solar can achieve absorption rates above 95%. This means that a vast majority of the sunlight incident on the solar collector is effectively captured, whether it's in the ultraviolet (UV), visible, or near-infrared (NIR) spectrum. On the other hand, emittance (ε) measures the coating's ability to resist re-radiating the captured heat in the mid-to-far infrared range, where thermal energy is typically lost. BTE Solar's coatings exhibit thermal emittance below 5%, a remarkable feat that significantly reduces heat leakage. This high α and low ε combination is what sets BTE Solar's selective coatings apart from ordinary black paint and is the key to high solar collector efficiency.

Strategic Dual-Line Production: Serving Global Markets with Both Blue and Black Coatings

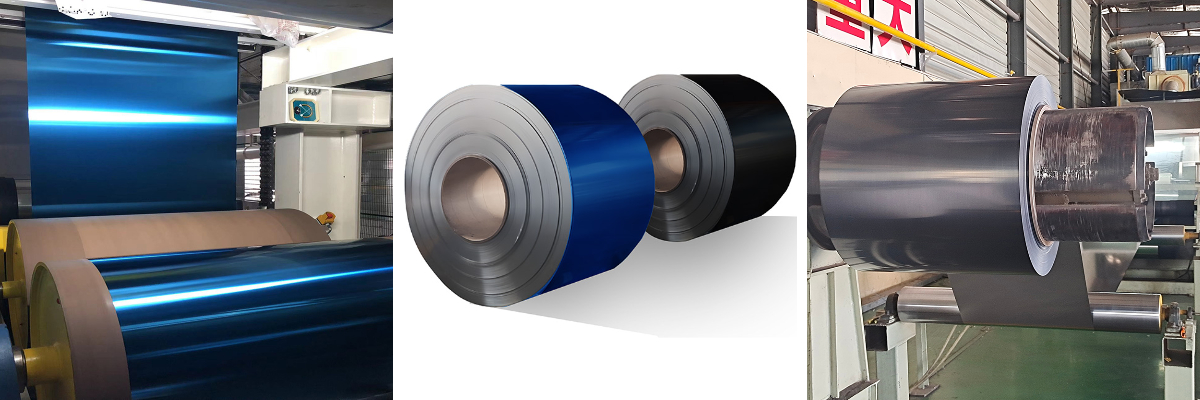

BTE Solar's Dual-Layer Coating Line One of the cornerstones of BTE Solar's success is its dual-layer coating line. This state-of-the-art production facility is capable of producing both blue and black membranes. The blue coatings, known for their distinct color due to interference effects in multilayer oxide structures, have a balanced high absorptance and low emittance. They are widely adopted in Europe and Asia, especially for residential flat-plate collectors. In fact, according to Solarico's 2024 market report, blue coatings dominate around 55 - 60% of the global selective coating demand. BTE Solar's blue coatings have found a niche in these regions, where they meet the strict efficiency standards such as EN12975/EN12976 in Europe and the growing demand for energy-efficient solutions in Asia. On the other hand, the black coatings, which are traditionally used for lower-cost collectors, still hold significance in certain markets. They typically consist of black chrome, black nickel, or black paint-based absorbers. While they may have a higher thermal emittance (often 10 - 15%) compared to the blue coatings, they are simple to produce and relatively low cost. BTE Solar's black coatings are particularly relevant in cost-sensitive markets in Africa, South Asia, and parts of Latin America. By offering both blue and black coatings, BTE Solar caters to a wide range of customers, from those looking for high-performance, long-lasting solutions to those on a tighter budget.

BTE Blue Selective Absorption Coating Production Workshop

The Foundation of Reliability: Precision Engineering for Long-Term Performance

Market Share and Global Presence Currently, BTE Solar's blue and black coatings combined hold a significant 60% market share in the selective coating market. The black coatings, in particular, have carved out a strong position in the cost-conscious segments. In Africa, for example, where the need for affordable solar solutions is high, BTE Solar's black coatings are being used in many small-scale solar projects. These projects are often aimed at providing basic heating and electricity needs in rural areas. The relatively low cost of the black coatings makes them an attractive option for local installers and end-users. In South Asia, with its large population and growing demand for energy, BTE Solar's black coatings are also making inroads. In countries like India, where there is a push to increase the use of renewable energy, the cost-effective black coatings are being used in a variety of applications, from small residential solar water heaters to community-level solar thermal systems. In Latin America, the market is more diverse. Residential consumers, who are often price-sensitive, favor BTE Solar's cost-effective black coatings for their solar installations. These coatings provide a viable solution for heating water and providing some level of thermal comfort in homes. At the same time, governments and hotels in the region are investing in more advanced blue and PVD (Physical Vapor Deposition) coatings for larger-scale projects. BTE Solar, with its dual-layer coating line, is well-positioned to meet both these demands, further strengthening its market share in the region.

Nanostructured Engineering and Durability Assurance BTE Solar's technological edge goes beyond just the types of coatings it produces. The company's nanostructured engineering is a game-changer. Precision control at the nanometer scale ensures that the optical properties of the coatings are consistent across large batches. This means that whether a customer orders a small quantity of coatings for a residential project or a large amount for a commercial solar thermal plant, they can expect the same high level of performance. Durability is another key aspect of BTE Solar's coatings. The coatings undergo rigorous thermal cycling, salt spray, and humidity resistance tests. These tests simulate decades of field exposure, ensuring that the coatings can withstand the harshest environmental conditions. In regions with high humidity, such as parts of Southeast Asia, BTE Solar's coatings have proven their ability to resist corrosion and maintain their performance over time. In desert areas with extreme temperature fluctuations, like the Middle East, the coatings continue to function effectively, providing reliable solar thermal solutions.

Operational Eco-Consciousness: How Sustainability Provides a Competitive Edge

Sustainability Focus In an era where environmental concerns are at the forefront, BTE Solar's sustainability focus is commendable. The company sources its materials with strict environmental compliance. This means that the raw materials used in the production of the selective coatings are obtained in an environmentally responsible manner. Additionally, BTE Solar actively reduces coating process emissions. By implementing advanced production techniques and investing in clean technologies, the company minimizes its carbon footprint. This not only benefits the environment but also positions BTE Solar as a leader in sustainable solar thermal technology. Customers, especially those in developed countries with strict environmental regulations, are more likely to choose BTE Solar's products due to their sustainable production methods. Industry Recognition and Future Directions BTE Solar's efforts have not gone unnoticed in the industry. According to Solarico's 2024 Comparative Coating Report, BTE Solar's absorptance (95 - 96%) and emittance (<5%) performance metrics are competitive with leading European suppliers. Moreover, its PVD multilayer coatings offer 20% lower costs than similar products from Western competitors, without sacrificing durability. This has earned BTE Solar a growing reputation as a global technology partner in the solar thermal supply chain, especially in emerging markets where cost-performance balance is crucial. Looking to the future, BTE Solar has an ambitious R&D roadmap. The company is exploring the development of smart coatings that can shift their optical properties with temperature. This would allow the solar collectors to adapt to changing environmental conditions, further enhancing their efficiency. Additionally, BTE Solar is working on ultra-low emittance membranes for extreme desert conditions. These membranes would be specifically designed to withstand the harsh temperatures and high solar radiation found in desert regions. Another area of focus is hybrid membranes integrating photovoltaic-thermal (PVT) applications. By combining solar thermal and photovoltaic technologies, BTE Solar aims to create more versatile and efficient energy systems. In conclusion, BTE Solar's dual-path strategy, with its focus on producing both blue and black coatings, has allowed the company to capture a significant 60% market share in the selective coating market. Its technological advancements, sustainability efforts, and industry recognition position it well for future growth. As the world continues to transition to renewable energy, BTE Solar's selective coatings will play a crucial role in providing affordable, efficient, and durable solar energy solutions worldwide.